Genau das finden Sie bei uns.

Mit Findling als Partner an der Seite sparen Sie bei der Beschaffung und beim Betrieb von Wälzlagern und profitieren von einer bestmöglichen Lieferperformance. Gleichzeitig legen wir als Unternehmen einen Fokus auf Nachhaltigkeit. So schonen wir gemeinsam Ressourcen und tragen zum Umweltschutz bei. Bereits seit vielen Jahren verbessern wir kontinuierlich unsere Umweltleistung. Unsere 230kWp Solaranlage auf den Dächern der Produktionshalle macht uns das gesamte Jahr - auch im Januar - autonom. Der überschüssige Strom deckt den Strombedarf von bis zu 77 Wohneinheiten. Zudem beziehen wir Fernwärme, die durch Abwärme der nahegelegenen Mineralöl-Raffinerie erzeugt wird. Wir sind somit unabhängig von Gas. Nicht zuletzt setzen wir bei der Lieferung unserer Produkte auf CO2-neutrale Logistikunternehmen - von der Verschiffung aus Asien bis zu Ihnen in die Werke.

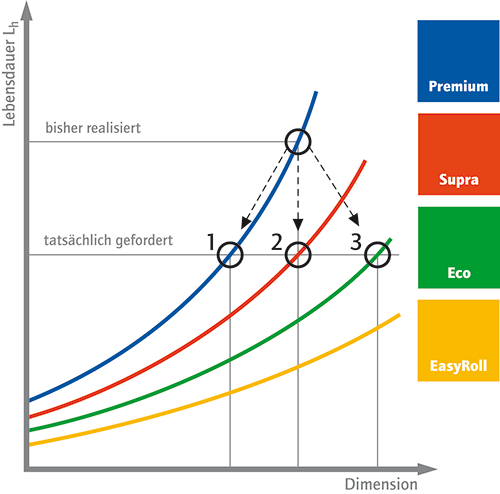

Wälzlager korrekt auslegen mit der ABEG®-Methode

Wer sich für ein technisch optimal ausgelegtes Wälzlager entscheidet, profitiert in zweifacher Hinsicht:

Einerseits von einer verlängerten Lebensdauer – das schont die Ressourcen. Andererseits zahlt der Kunde nur für das, was er wirklich benötigt – das schont den Geldbeutel. Mit ABEG® (Advanced Bearing Expert Group) hat Findling Wälzlager eine transparente und berechenbare Entscheidungsgrundlage zur Vermeidung von Über- und Unterdimensionierung von Wälzlagern geschaffen.

Ergebnis der Beratung ist eine Empfehlung für eine der vier möglichen Leistungsklassen Premium, Supra, Eco und EasyRoll, über die sich Einsparpotenziale von 25-30% realisieren lassen.