Bearing solutions for food technology

The food and beverage industry is subject to high hygiene standards. Since conventional roller bearing designs quickly reach their limits in these applications, Findling offers different models with improved performance for use in the food industry. It must be ensured that the bearing technology is able to withstand demanding cleaning procedures, for example with a high-pressure cleaner, alkaline solutions or sterilization fluids, and substantial temperature fluctuations. In addition, no lubricant may leak from the roller bearing and end up in its surroundings. This may compromise the product or contaminate the packaging. Findling supplies various bearing types in all four ABEG® performance classes, including ball bearings in a wide variety of designs, s-type bearing with housing units, and cam followers and yoke type track rollers. Whether it’s high-performance plastic, ceramics, new steel qualities or modern coating concepts – the choice of material for each bearing component is based on the respective application, as is the choice of the right food-grade lubricant and application-specific seals. Our bearings meet the highest demands for high durability and reliable operational safety and offer long service lives with minimum need for maintenance.

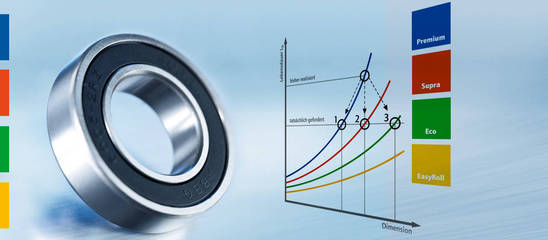

ABEG® in the food industry

The food industry is a cross-sectoral industry (conveying technology, power transmission technology, actuators, fluid technology...) where the requirements of a very wide range of special industries come together. The more complex the selection of optimum bearing technology becomes, the more added value our ABEG® method offers you.

- Rapid selection of the right bearing series

- Large selection of functional characteristics combined with ABEG® performance classes

- Responsible handling of special solutions that drive up costs

Deep-groove ball bearings ensure frictionless operation – food processing machinery

Deep-groove ball bearings have a wide variety of uses and are the most frequently used roller bearings. Due to the different requirements in industrial applications, these bearing types are available in various designs. For example, a bearing’s corrosion protection and seals play an important role for applications in the food industry. When you think of waffle irons you usually think of the delicious product and not so much of the extreme operating conditions that the components in the machines have to withstand. However, the fact is that ambient temperatures of up to 260 °C and contact with baking residues, waffle dust, and grease pose a challenge for many components, including any roller bearings that are installed.

Housing bearings for rough conditions

The combination of a bearing insert and housing allows these products to be installed especially easily. Housing bearings with high corrosion protection are exceptionally resistant to rough conditions. Housing bearings from the Clean and CERABALL series are particularly convincing. Findling Wälzlager offers the right solution for a wide variety of applications, for example with a Geomet 321 coating for metal surfaces. This thin-layer coating of zinc, aluminum slats and a mineral sealant protects housings in a salt spray test according to DIN 50021 for more than 1,000 hours – and even longer with an additional cover layer. The combination with bearing inserts made of stainless steel results in an interesting alternative to solutions in solid stainless steel in terms of price and economy.

Cam followers and yoke type track rollers

Ready-to-mount systems such as cam followers and yoke type track rollers are also available in different materials, including designs in stainless steel for clean room and food machines. For use in freezers and cool storage warehouses, a grease with operating temperatures of -50° is available. In the stainless steel design, the miniature cam followers have high corrosion resistance and resilience under rough operating conditions. They are particularly suitable for environments that have high moisture and/or humidity but are as oil-free as possible. Certain types can also be used in clean room applications, where there is a higher risk of corrosion.