The ABEG® method for professional rolling bearing procurement

The performance and thus the service life of products are as diverse as the prices of manufacturer's plants for rolling bearings. Findling has the solution to this problem: The ABEG® method (Advanced Bearing Expert Group) thus offers a comprehensible and transparent basis for decision making for selecting technically and economically optimum roller bearings.

But ABEG® is not just about making a sound selection, but also about certainty and flexibility in roller bearing procurement. If a bearing is not available or too expensive, the customer can simply opt for a product from a different plant with the same or a higher performance class.

ABEG brochure

Four performance classes for a simple selection

The idea of ABEG®:

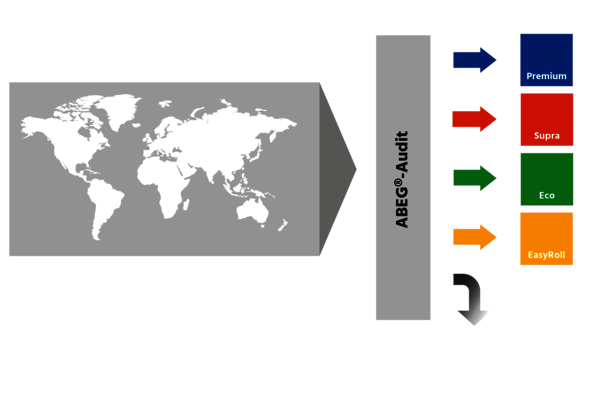

The rolling and plain bearings are allocated to one of the four performance classes, Premium, Supra, Eco and EasyRoll, with Premium currently representing the most state-of-the-art technology and meeting particularly demanding requirements for service life. The EasyRoll category, however, includes products that are intended for use under lower loads in cost-sensitive areas. The classification takes design-related load rating differences and production method as well as raw materials and components such as grease into consideration. This makes it possible to create a diverse range of rolling bearing technology with an extremely wide variety of performance levels.

The advantages for customers are clear.

Instead of dealing with the question of the actual service life of a product, which can hardly be determined by the user, the ABEG® pre-classification is used.

The ABEG® audit—for optimum rolling bearing quality

The ABEG® approach commits Findling to permanent monitoring of rolling bearing production plants. Findling’s expertise in terms of products, manufacturing techniques, technologies and production processes forms the basis for the ABEG® audit. This comprehensive qualification process for reliable classification in the four ABEG® performance classes not only takes into account quality and environmental management according to ISO 9001 or ISO 14001, but goes beyond standards: Specific, quality-relevant aspects of the manufacturing process of rolling bearings and the sustainability and development potential of the respective production systems are checked.

Quality? Of course!

Find out about our advanced quality management.

to quality management

Avoid overdimensioning

With ABEG®, Findling Wälzlager has created a transparent and reliable basis for decision-making in order to prevent over- and undersizing of roller bearings. Achieve savings potentials of 25-30%.

The background:

There is a tendency on the market towards overdimensioning of the service life of rolling bearings—for safety reasons. It doesn’t have to be that way. Findling has added the ABEG® factor to the life calculation of rolling bearings. Using the service life actually required as a basis, the products that meet the operating and environmental conditions without compromise can be determined in a manufacturer-independent way. The user can now make their choice based on economic criteria and will really only pay for what they need.

Nevertheless, they should still play it safe:

This is because the different performance classes do not say anything about the quality; whether it’s Premium or Eco — in Findling’s portfolio, all bearing technology meets the strict quality requirements without exception.

You can find out more about the service life calculation of rolling bearings in our training sessions:

Useful ABEG® tools for rolling bearing design

Selection wizards, because they present multiple possible alternatives in the results window in a clear manner: All potentially suitable bearings are shown in color. This makes it possible to select roller or plain bearings quickly and accurately in a way that is always financially optimal.

- The proprietary ABEG Quickfinder online tool is based on a database containing all designs and ABEG product lines. Roller bearings that meet the technical requirements defined on the design side can be found quickly and independently of the manufacturer

- ABEG® Quickfinder Professional goes one step further: The CAE software (Computer-Aided Engineering) is used for the calculation and design not only of roller bearings in accordance with ISO 281, but also of many other common machine elements, for example shafts, spur gears, planetary stages, springs and fits.

Start the rolling bearing calculation now using the ABEG® Quickfinder!