Bearing inserts

Bearing inserts are deep-groove ball bearings for installation in housings and are an economical solution. Bearings with a spherical outer ring compensate for static misalignment of the shaft. The designs differ in terms of their fixing possibilities, holding force and ease of installation. Bearing inserts can be optimized for the application both technically and economically thanks to a wide variety of designs and special properties.

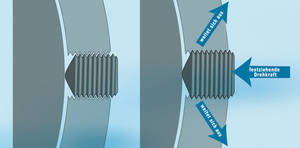

S-type bearing

Bearing inserts with an eccentric ring are also commonly called S-type bearings . They are fixed in place on the shaft by rotating the eccentric ring and secured by means of a grub screw. The “clamping” results in a slight deformation of the inner ring and therefore higher radial runout accuracy at higher speeds. This design is preferred by European manufacturers, but it is also more expensive because it involves more mechanical parts and costlier processing of the inner ring. These bearings are therefore not suitable for alternating directions of rotation because the eccentric ring on the S-type bearing can more easily become loose.

Bearing insert with BPSS

BPSS is an abbreviation for "bullet point set screw" and is a refinement of the ball pressure screw. The special design makes self-expansion possible and guarantees a secure fit, even in cases of strong vibrations. At the same time, the inner ring is deformed significantly less as a result of the tightening, meaning that the radial runout accuracy is maintained.

Range of bearing inserts with a spherical outer ring

| ABEG designation | Design | available in ABEG® performance classes | ||

|---|---|---|---|---|

| UC | bearing insert with grub screw, inner ring elongated on both sides |  |  |  |

| UB | bearing insert with grub screw, inner ring elongated on one side |  |  |  |

| EW | s-type bearing with eccentric,, inner ring elongated on both sides |  |  |  |

| EN | s-type bearing with eccentric, inner ring elongated on one side |  |  |  |

| UK | bearing insert with conical inner ring, installation with adapter sleeve (accessory) |  |  |  |

| ZK | bearing insert similar to UK with integrated adapter sleeve (patented) |  | ||

| CS | bearing insert without elongated inner ring, installation on shaft tolerance |  |  |  |

| NC | bearing insert with slotted inner ring, clamp ring with cylinder head bolt |  | ||

- Bearing clearance classes C2, CN, C3 and C4

- | Fa - axial load

- | Noise test by decibels

- | Noise test by vibration level for deep groove ball bearings

- | Noise test by vibration level for tapered roller bearings

- | P - dynamic equivalent load

- | PN/P0 tolerance class for radial bearings (without tapered roller bearings)

Technical information

Inadequate sealing can allow external environmental conditions to have an extremely negatively impact on running characteristics and thus a bearing’s service life. For this reason, bearings must be protected by seals.

At the same time, seals also prevent lubricants from leaking.

| Series | Seal type | Effect |

|---|---|---|

| UC, EW, NC | 2RS seal with flinger ring in front | very effective sealing against fine and coarse contamination |

| UB, EN, CS | 2RS seal with inner steel reinforcement; design with outer steel reinforcement also available | effective sealing against fine contamination |

| UK | bearing insert with conical inner ring, installation with adapter sleeve (accessory) | |

| NC | bearing insert with slotted inner ring, clamp ring with cylinder head bolt |

Special designs for sealing

Bearing inserts are supplied pre-greased with a universal grease as standard. Low or high-temperature greases can also be supplied on request. Bearing inserts usually have a relubrication hole or circumferential groove with a lubrication hole.

Designs

D1: can be relubricated

OS: without lubrication hole

As standard, bearing inserts are manufactured from 100Cr6 chrome steel or an equivalent thereof.

Various series are also available in stainless steel (AISI440C, AISI420). These products have the “-SS” suffix.

FYH supplies hybrid bearing inserts with balls made of ceramic or solid ceramic. See our housing bearing range.

Additional information

| ABEG | FYH | JIB | SKF | FAG/INA | NTN/SNR | ASAHI | NSK | RHP |

|---|---|---|---|---|---|---|---|---|

| UC-200 | UC200 | UC200 | YAR-2F | GYE-KRRB | UC200 | UC200 | UC200 | 1000G |

| UC200 / LLJ | UC200 / LLJ | T1000G | ||||||

| YAR2-2F | 1000GFS | |||||||

| UB-200 | SB200 | SB200 | YAT2 | GAY-NPPB | AS200 | B200 | AS200 | 200G |

| EN-200 | SA200(F) | SA200 | YET2 | GRAE-NPPB | AEL200 | KH200+ER | AEL200 | 1200ECG |

| EW-200 | NA200 | HC200 | YEL2-2F | GE-KRRB | UEL200 | UG200+ER | UEL200 | 1000DECG |

| GE-KPPB-3 | ||||||||

| UK-200 | UK200 | UK200 | YSA2-2F | GSH-RRB | UK200 | UK200 | UK200 | 1000DECGFS |

| CS-200-2RS | SC200 | SC200 | 1726200-2RS1 | 200-NPPB | CS200LLU | CS200ZZ | CS200LLU | 1000KG |

| UC-300 | UC300 | UC300 | UC300 | UC300 | UC300 | 1726200-2RS | ||

| NC-200 | NC200 | |||||||

| EW-200-S | ERC200 | UELS-N | ||||||

| UC-200-S | ER200 | |||||||

| UR200 | RB200 | |||||||

| RAE-NPP-NR | RAE-NPP-NR |

Typical assembly and handling mistakes

- Lack of expertise

- Lack of qualified personnel

- Adapter sleeve tightening torque exceeded → bearing clearance decreases too sharply → rolling elements become clamped between the inner and outer ring → premature failure

- Adjusting screw tightening torque exceeded → possible crack in the inner ring → no more securing on the shaft