The way is the goal

The Golden Twenties brought an economic upswing, which continued with the political easing and allowed the young company to survive the Third Reich largely unscathed. The Findling goods trading company, founded in Berlin, later became a rolling bearing production facility.

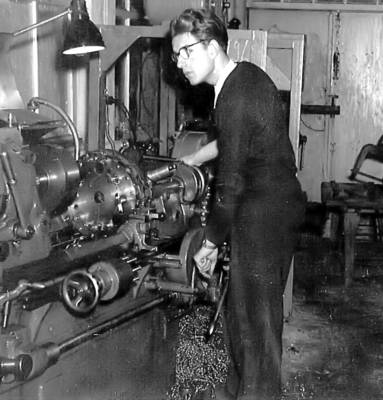

In 1945 Anton Findling moved back to his roots in Baden, at that time the resurrected core of German mechanical engineering. Despite these economically turbulent years and the region split into post-war zones, Anton Findling managed to successfully establish a production facility for ball bearings: Ball bearings, like other types of rolling bearings later on, were in great demand during the period of reconstruction and the advancing industrialisation. Axial thrust bearings of the 51, 52 and 53 series were manufactured at the new location in Ettlingen, a suburb of Karlsruhe.

Eighteen years later, due to the death of the founder, his son Klaus-Peter Findling took over the company and became the first German entrepreneur to import Japanese rolling bearings. This is how he justified his pioneering role in the interests of global sourcing, long before this term was "globalised". From 1975 onwards, the broad product range was systematically expanded through cooperation with manufacturers from Eastern Europe, Korea and China. Thanks to Findling's global activities, innovative products from qualified manufacturers from all over the world could be integrated into the portfolio, which was what made the later "birth" of the ABEG® method possible in the first place.

The foundation of this success is ABEG®

The selection and calculation method, which is based on performance characteristics, allows users to determine technically and economically optimal rolling bearings.

With the experience and product expertise gained from thousands of customer requirements, a unique range of services has been developed, from application technology consulting, damage analysis and life cycle tests to manufacturer-independent training courses.

Thanks to our own production facility for specially greased and modified rolling bearings, complex customer requirements can be implemented flexibly and promptly.

Findling also brings this expertise to consulting projects: Findling supports the auditing of rolling bearing suppliers, their quality and performance testing as well as logistical and technical aspects of series supply. Digitalisation in the service department is one of the key factors in providing individual solutions to rolling bearing technology problems.

The innovative strength of the company, which is now in its third generation as an owner-managed company, is unbroken: In each generation, the enthusiasm and feel for the needs of the market in rolling bearing technology has developed at an increasing pace.