Temperature, load, speed – challenges for pumps

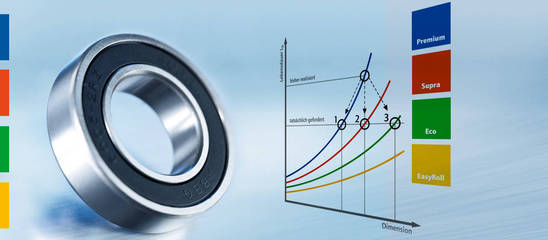

Fluid technology involves the use of countless roller bearings (cylindrical roller bearings, needle-roller bearings (heavy-section), double-row angular contact ball bearings, hybrid bearings). To sum it up, it’s a big investment. It’s a good thing if you can find an economical alternative without sacrificing the technical suitability of a product. Findling Wälzlager offers just the thing for you in its comprehensive ABEG® portfolio, which includes around 22,000 products.

- low internal heating at high speeds

- poor heat dissipation requires temperature-stable roller bearing technology

- application-oriented, optimized lubricants

- high dynamic load ratings for long service lives

ABEG® in fluid technology

High loads and medium speeds under a high degree of thermal influence place special demands on lubricants. Accordingly, the focus is on highly resilient and thermally stable roller bearing greases, which can make up a considerable proportion of product costs. Using the ABEG®-method and the option of flexibly combining lubricants and our ABEG® performance classes, we help design engineers create savings potential while achieving the desired service life. In doing so, we create economic maneuvering room for industry-specific products with an excellent service life.

Product recommendations for fluid technology

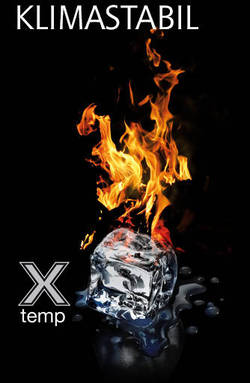

Xtemp series high-temperature bearings

Depending on their design, Xtemp bearings are made for use in a temperature range of -60 °C to > 500 °C. Current-insulating, low-corrosion or coated variants are also available as options. The basis for all the designs are deep-groove ball bearings, to which special modifications were made, including the selection of a suitable material, the optimization of the bearing clearance, special greases and solid lubricants, a special seal, and, if necessary, thermal stabilization.

Equipped with all this, Xtemp series bearings deliver a convincing performance with an extended service life: Compared to the standard premium bearings available on the market, their service life is 1.2 to 1.5 times longer at an operating temperature of 120 °C. Upon request, there are also a lot of other functional characteristics that can be achieved, such as minimal start-up behavior, no grease leakage at high temperatures, no need for maintenance, and particularly long maintenance intervals. Unlike other premium or special bearings, the Xtemp bearings for sustained temperature ranges of -40° to 150° C are impressive not only because of their good price/performance ratio, but also because of their rapid availability as standard bearing products.

All Xtemp solutions are part of Findling’s ABEG® eXtreme product range, the development of which especially prioritized aspects such as purchasing costs and delivery times as well as technical functionality.

Angular contact ball bearings, double-row

Various contact angles

Double-row angular contact ball bearings are available in different contact angles. Ideal for tailoring to your application!

Double-row angular contact ball bearings consist of two angular contact ball bearings combined in an X arrangement that are united in a single assembly and can handle both radial forces and axial forces on both sides. By contrast, there are designs with a filling groove in order to increase the load rating using a larger number of balls. These designs are only one-sided, but despite this they can handle very high axial loads and have a steel serpentine cage.

The contact angle α (alpha) determines the optimum ratio of radial and axial forces. You can find typical designs on the product page for angular contact ball bearings.

ABEG® eXtreme series

Findling Wälzlager’s special product range is divided into four series: Xforce, Xspeed, Xtemp, and Xclean. This allows different requirements to be met with respect to operating conditions. Xforce bearings are solutions for high loads at low rotation speeds in which there are unfavorable tribological conditions and lubrication film build-up cannot reliably occur with standard solutions. During the development of the Xspeed series, on the other hand, high speeds and energy efficiency were the focus. The Xtemp series ensures temperature stability in excessively hot or cold conditions. The Xclean series provides robust bearing technology for corrosive ambient conditions as well as special designs for clean room applications.