Top speed endurance runner

The problem: Long service lives, high speeds, guaranteed safety, reliable sealing technology, a low price and a short delivery time: these requirements for roller bearings used in high speed applications have not been met all at once until now. It was truly challenging to search for a solution, and things usually ended with expensive, hard-to-deliver products or special bearings.

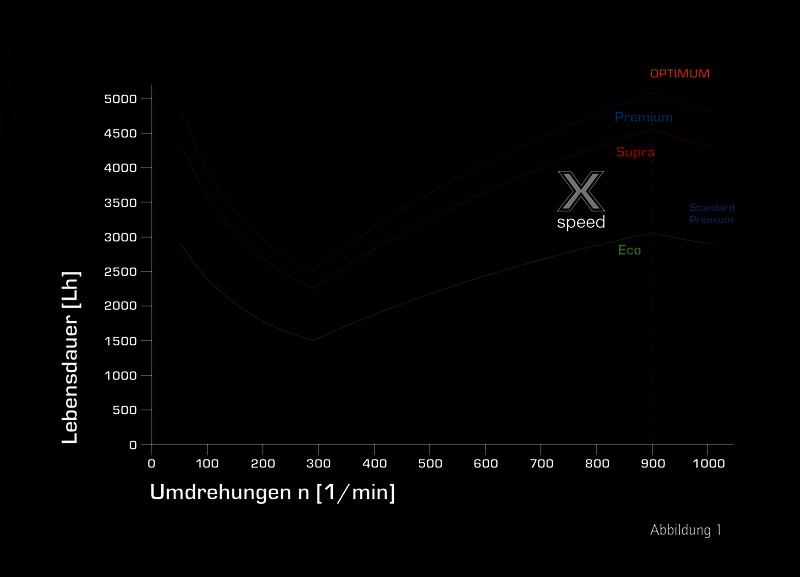

The solution: Xspeed series ABEG® roller bearings. Proven bearing technology is combined with components for high speeds, such as seals and special lubrication, and tested on the test rig to find particularly high-performance combinations for applications involving high speeds. After endurance and comparison tests with selected types, it was possible to triple the actual service life of Xspeed series bearings compared to the reference values for standard premium bearings. ince ABEG® products are, in principle, technically and economically optimum solutions, Xforce high-performance bearings are significantly less expensive than similar premium or special bearings. Furthermore, customers are no longer forced to acquire costly product properties that they don’t even need with standard premium bearings.

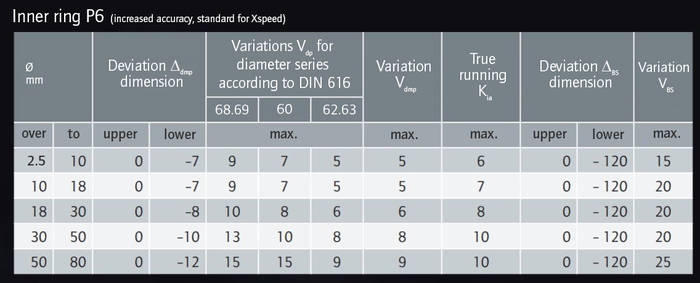

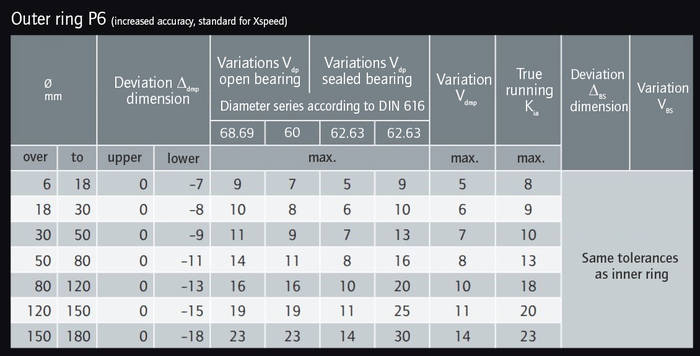

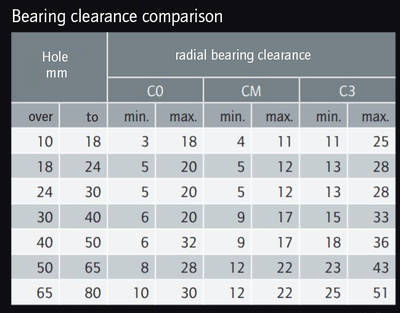

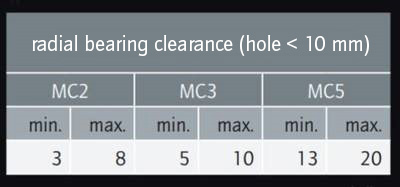

Improved running characteristics at maximum speeds go hand in hand with higher requirements for surface quality and raceway profiles. Xspeed bearings are therefore manufactured in tolerance class P6 with increased precision and radial runout accuracy. The bearing clearance is adapted to the high speeds by tightening the tolerance. This combination makes it possible to optionally adjust the residual bearing clearance based on the selection of the housing and shaft fit. A special high-purity, viscous and quiet grease with excellent start-up behavior ensures optimum operating conditions at high speeds:

Inner ø | Designation | Design | Outer ø | Width | Radius | Load rating | Speed limit | Weight | Cu | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| d(mm) | Type | O1) | ZZ | 2RS | D(mm) | W(mm) | r(mm) | Cstat(N) | Cdyn(N) | nG grease (1/min) | nG oil (1/min) | m(kg) | Cu(N) |

| 10 | 6000 | X | X | X | 26 | 8 | 0.30 | 1,960 | 4,750 | 30,000 | 36,000 | 0.019 | 82.1 |

| 10 | 6200 | X | X | X | 30 | 9 | 0.60 | 2,390 | 5,400 | 25,000 | 30,000 | 0.030 | 100.1 |

| 10 | 6300 | X | X | X | 35 | 11 | 0.60 | 3,500 | 8,520 | 23,000 | 27,000 | 0.054 | 146.6 |

| 10 | 6800 | X | X | X | 19 | 5 | 0.30 | 925 | 1,830 | 33,000 | 40,000 | 0.005 | 38.8 |

| 10 | 6900 | X | X | X | 22 | 6 | 0.30 | 1,270 | 2,700 | 32,000 | 38,000 | 0.009 | 53.2 |

| 12 | 6001 | X | X | X | 28 | 8 | 0.30 | 2,360 | 5,400 | 29,000 | 33,000 | 0.021 | 100.1 |

| 12 | 6201 | X | X | X | 32 | 10 | 0.60 | 3,100 | 7,280 | 23,000 | 28,000 | 0.036 | 127.8 |

| 12 | 6301 | X | X | X | 37 | 12 | 1.00 | 4,200 | 10,100 | 21,000 | 25,000 | 0.060 | 176.0 |

| 12 | 6801 | X | X | X | 21 | 5 | 0.30 | 1,040 | 1,920 | 32,000 | 38,000 | 0.006 | 43.6 |

| 12 | 6901 | X | X | X | 24 | 6 | 0.30 | 1,460 | 2,890 | 31,000 | 36,000 | 0.011 | 61.2 |

| 15 | 6002 | X | X | X | 32 | 9 | 0.30 | 2,850 | 5,850 | 25,000 | 29,000 | 0.030 | 119.0 |

| 15 | 6202 | X | X | X | 35 | 11 | 0.60 | 3,750 | 8,060 | 20,000 | 25,000 | 0.046 | 150.8 |

| 15 | 6302 | X | X | X | 42 | 13 | 1.00 | 5,450 | 11,900 | 19,000 | 22,000 | 0.082 | 228.3 |

| 15 | 6802 | X | X | X | 24 | 5 | 0.30 | 1,260 | 2,080 | 28,000 | 32,000 | 0.007 | 52.8 |

| 15 | 6902 | X | X | X | 28 | 7 | 0.30 | 2,240 | 4,360 | 27,000 | 31,000 | 0.016 | 86.3 |

| 17 | 6003 | X | X | X | 35 | 10 | 0.30 | 3,350 | 6,800 | 23,000 | 26,000 | 0.039 | 140.3 |

| 17 | 6203 | X | X | X | 40 | 12 | 0.60 | 4,750 | 9,950 | 18,000 | 22,000 | 0.065 | 192.7 |

| 17 | 6303 | X | X | X | 47 | 14 | 1.00 | 6,550 | 14,300 | 16,000 | 19,000 | 0.113 | 274.4 |

| 17 | 6803 | X | X | X | 26 | 5 | 0.30 | 1,720 | 2,810 | 25,000 | 30,000 | 0.008 | 72.1 |

| 17 | 6903 | X | X | X | 30 | 7 | 0.30 | 2,580 | 4,650 | 25,000 | 29,000 | 0.018 | 108.1 |

| 20 | 6004 | X | X | X | 42 | 12 | 0.60 | 5,050 | 9,950 | 18,000 | 21,000 | 0.069 | 211.6 |

| 20 | 6204 | X | X | X | 47 | 14 | 1.00 | 6,650 | 13,500 | 16,000 | 18,000 | 0.107 | 278.6 |

| 20 | 6304 | X | X | X | 52 | 15 | 1.10 | 7,900 | 16,800 | 14,000 | 17,500 | 0.142 | 331.0 |

| 20 | 6804 | X | X | X | 32 | 7 | 0.30 | 2,470 | 4,030 | 23,000 | 28,000 | 0.015 | 103.5 |

| 20 | 6904 | X | X | X | 37 | 9 | 0.30 | 3,700 | 6,400 | 20,000 | 24,000 | 0.036 | 155.0 |

| 25 | 6005 | X | X | X | 47 | 12 | 0.60 | 6,550 | 11,900 | 16,000 | 19,000 | 0.080 | 245.1 |

| 25 | 6205 | X | X | X | 52 | 15 | 1.00 | 7,850 | 14,800 | 13,000 | 16,000 | 0.125 | 328.9 |

| 25 | 6305 | X | X | X | 62 | 17 | 1.10 | 11,600 | 23,400 | 12,000 | 14,000 | 0.226 | 456.6 |

| 25 | 6805 | X | X | X | 37 | 7 | 0.30 | 2,950 | 4,360 | 18,000 | 23,000 | 0.020 | 123.6 |

| 25 | 6905 | X | X | X | 42 | 9 | 0.30 | 4,550 | 7,050 | 17,000 | 21,000 | 0.042 | 190.6 |

| 30 | 6006 | X | X | X | 55 | 13 | 1.00 | 8,300 | 13,800 | 13,000 | 15,000 | 0.114 | 347.7 |

| 30 | 6206 | X | X | X | 62 | 16 | 1.00 | 11,300 | 20,300 | 12,000 | 14,000 | 0.200 | 473.4 |

| 30 | 6306 | X | X | X | 72 | 19 | 1.10 | 16,000 | 29,600 | 10,000 | 12,000 | 0.350 | 628.4 |

| 30 | 6806 | X | X | X | 42 | 7 | 0.30 | 3,650 | 4,700 | 16,000 | 19,000 | 0.025 | 152.9 |

| 30 | 6906 | X | X | X | 47 | 9 | 0.30 | 5,000 | 7,280 | 16,000 | 19,000 | 0.048 | 209.5 |

| 35 | 6007 | X | X | X | 62 | 14 | 1.00 | 10,300 | 16,800 | 12,000 | 14,000 | 0.150 | 431.5 |

| 35 | 6207 | X | X | X | 72 | 17 | 1.10 | 15,300 | 27,000 | 10,000 | 12,000 | 0.290 | 641.0 |

| 35 | 6307 | X | X | X | 80 | 21 | 1.50 | 19,100 | 35,100 | 8,800 | 10,000 | 0.460 | 800.2 |

| 35 | 6807 | X | X | X | 47 | 7 | 0.30 | 4,050 | 4,900 | 13,000 | 17,000 | 0.029 | 169.7 |

| 35 | 6907 | X | X | X | 55 | 10 | 0.30 | 7,450 | 11,200 | 13,000 | 17,000 | 0.074 | 312.1 |

| 40 | 6008 | X | X | X | 68 | 15 | 1.00 | 11,600 | 17,800 | 10,000 | 12,000 | 0.190 | 481.8 |

| 40 | 6208 | X | X | X | 80 | 18 | 1.10 | 19,000 | 32,500 | 8,800 | 10,000 | 0.370 | 754.7 |

| 40 | 6308 | X | X | X | 90 | 23 | 1.50 | 24,000 | 42,300 | 7,800 | 9,200 | 0.650 | 1005.4 |

| 40 | 6808 | X | X | X | 52 | 7 | 0.30 | 4,400 | 5,100 | 12,000 | 15,000 | 0.033 | 184.3 |

| 40 | 6908 | X | X | X | 62 | 12 | 0.30 | 10,200 | 14,600 | 11,000 | 13,000 | 0.110 | 427.3 |

| 45 | 6009 | X | X | X | 75 | 16 | 1.00 | 15,100 | 22,100 | 9,200 | 11,000 | 0.240 | 632.6 |

| 45 | 6209 | X | X | X | 85 | 19 | 1.10 | 21,600 | 35,100 | 7,800 | 9,200 | 0.420 | 854.6 |

| 45 | 6309 | X | X | X | 100 | 25 | 1.50 | 32,000 | 55,300 | 7,000 | 8,200 | 0.840 | 1340.6 |

| 50 | 6010 | X | X | X | 80 | 16 | 1.00 | 16,600 | 22,900 | 8,400 | 9,800 | 0.260 | 695.4 |

| 50 | 6210 | X | X | X | 90 | 20 | 1.10 | 23,200 | 37,100 | 7,100 | 8,300 | 0.470 | 971.9 |

| 50 | 6310 | X | X | X | 110 | 27 | 2.00 | 38,500 | 65,000 | 6,400 | 7,500 | 1.090 | 1612.9 |

| Please request bearings with an inner diameter (d) of 55 mm and above, as these are not stock goods. | |||||||||||||

| 55 | 6011 | X | X | X | 90 | 18 | 1.10 | 21,200 | 29,600 | 7,700 | 9,000 | 0.370 | 888.1 |

| 55 | 6211 | X | X | X | 100 | 21 | 1.50 | 29,200 | 46,200 | 6,400 | 7,600 | 0.610 | 1223.3 |

| 55 | 6311 | X | X | X | 120 | 29 | 2.00 | 45,000 | 74,100 | 5,800 | 6,800 | 1.350 | 1885.2 |

| 60 | 6012 | X | X | X | 95 | 18 | 1.10 | 23,200 | 30,700 | 7,100 | 8,300 | 0.390 | 971.9 |

| 60 | 6212 | X | X | X | 110 | 22 | 1.50 | 36,000 | 55,300 | 6,000 | 7,300 | 0.800 | 1508.2 |

| 60 | 6312 | X | X | X | 130 | 31 | 2.10 | 52,000 | 85,200 | 5,400 | 6,300 | 1.700 | 2178.5 |

| 65 | 6013 | X | X | X | 100 | 18 | 1.10 | 25,000 | 31,900 | 6,700 | 8,000 | 0.440 | 1047.3 |

| 65 | 6213 | X | X | X | 120 | 23 | 1.50 | 40,500 | 58,500 | 5,500 | 7,000 | 0.990 | 1696.7 |

| 65 | 6313 | X | X | X | 140 | 33 | 2.10 | 60,000 | 97,500 | 5,000 | 6,000 | 2.100 | 2513.6 |

| 70 | 6014 | X | X | X | 110 | 20 | 1.10 | 31,000 | 39,700 | 6,300 | 7,100 | 0.600 | 1,298.7 |

| 70 | 6214 | X | X | X | 125 | 24 | 1.50 | 45,000 | 63,700 | 5,100 | 6,100 | 1.100 | 1885.2 |

| 70 | 6314 | X | X | X | 150 | 35 | 2.10 | 68,000 | 111,000 | 4,500 | 5,300 | 2.500 | 2848.8 |

| 75 | 6015 | X | X | X | 115 | 20 | 1.10 | 33,500 | 41,600 | 5,800 | 7,000 | 0.640 | 1,403.4 |

| 75 | 6215 | X | X | X | 130 | 25 | 1.50 | 49,000 | 68,900 | 4,800 | 5,600 | 1.200 | 2052.8 |

| 75 | 6315 | X | X | X | 160 | 37 | 2.10 | 76,500 | 119,000 | 4,300 | 5,000 | 3.000 | 3204.9 |

| 80 | 6016 | X | X | X | 125 | 22 | 1.10 | 40,000 | 49,400 | 5,500 | 6,500 | 0.850 | 1675.7 |

| 80 | 6216 | X | X | X | 140 | 26 | 2.00 | 55,000 | 72,800 | 4,500 | 5,300 | 1.400 | 2220.4 |

| 80 | 6316 | X | X | X | 170 | 39 | 2.10 | 86,500 | 130,000 | 4,000 | 4,800 | 3.600 | 3623.8 |

| 1) O = This design is open and therefore ungreased (only oiled) | |||||||||||||

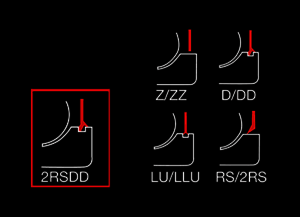

Optimally protected

The bearing’s self-heating plays an important role in high-speed applications. It changes the characteristics and performance of the lubricant and can be reduced by using the right seal. Excellent results were achieved with the 2RSDD seal variant (axially abutting contact rubber seal guided in a groove on both sides). It was possible to reduce the self-heating by 10 °C compared to a standard RS seal, which directly affects the bearing’s service life. An even lower-friction (2RW) variant and a non-contact variant (LLB) are optionally available.

Tests on the performance test rig also showed that Xspeed bearings have significantly lower vibration acceleration in the noise test than the premium reference class. They also reach a considerably lower operating temperature with the same performance parameters.

Lubricant matters

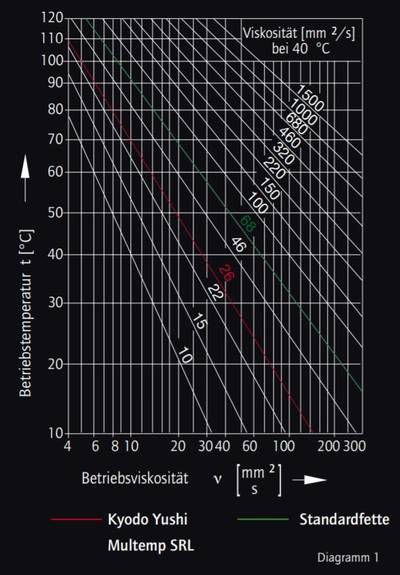

For the Xspeed series, we use Kyodo Yushi’s “MultempSRL” grease. See the table below for other greases recommended for high speeds.

Xspeed bearings are equipped with a high-performance grease for a temperature range of -50 to +150 °C. Bearings with C3 bearing clearance are equipped with a high purity high temperature grease up to +180 °C. This grease can increase the optimal operating temperature even further. At +177 °C, it still has a service life according to ASTM D 3336 of over 750 hours.

| Grease type | Thickener | Base oil | Viscosity [40 °C in mm/s ] | Price level | Temperature range [°C] | Water resistance | Corrosion protection | Pressure resistance | Noise behavior | Speed |

|---|---|---|---|---|---|---|---|---|---|---|

| Multemp SRL | Lithium complex soap | Ester oil | 26 | + | –50 °C to 150 °C | + | ++ | - | + | ++ |

| Klüberquiet BQ 42-32 | Lithium soap | Ester oil | 25 | 0 | –50 °C to 150 °C | ++ | + | 0 | +++ | + |

| Klüberquiet BQ 72-72 | Polyurea | Ester oil | 70 | 0 | –45 °C to 180 °C | +++ | ++ | + | ++ | ++ |

| Klüberspeed BF 72-22 | Polyurea | Ester oil, PAO | 22 | 0 | –50 °C to 120 °C | +++ | ++ | + | ++ | +++ |

| Klüberspeed BF 42-12 | Lithium complex soap | Ester oil, PAO | 24 | 0 | –50 °C bis 120 °C | + | ++ | - | 0 | +++ |

Find out more about lubricants and special greases here

Our Xspeed products comply with tolerance class P6, for higher radial runout accuracy in high-speed applications. The inner diameter can also be manufactured in P5 on request. This also makes it possible to perfectly set the operating clearance (bearing clearance during operation) in the interplay between housing and shaft fit.

Practicality guaranteed

Xspeed series bearings are designed for high speeds, as required in electric motors, pumps and compressors, fans, rotary encoders, air-conditioning systems, household appliances and office technology. They provide:

- high speeds

- a high level of smoothness

- minimal operational noise

- significantly reduced internal heating

- long service lives

- optimum energy efficiency.