Cam followers, yoke type track rollers, track rollers, track rollers with profiled outer ring

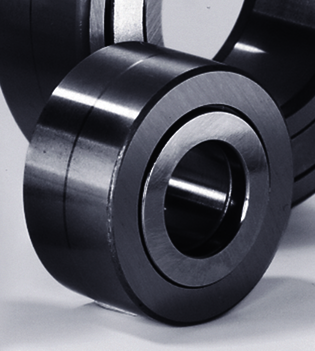

Ball and needle-roller bearings with a thick-walled outer ring

Track rollers have a thick-walled outer ring that usually has a profile optimized for high loads. The outer ring functions as a rolling surface to the raceway.

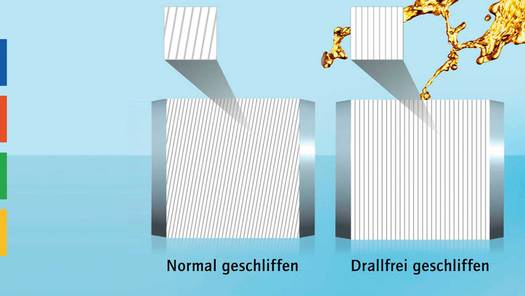

Yoke type track rollers, cam followers, and running rollers have an outer ring that runs directly on a mating track. This mating track can be a rail, guide track or cam disk that is flat or curved. The outer ring replaces the housing and is therefore very thick so that it can absorb deflections and stresses. Edge pressure occurs in cases where the outer ring frequently tips toward the mating track. In order to prevent this, the outer ring sheath is designed to be predominantly spherical or with a specific spherical profile.

Yoke type track rollers based on roller bearings. They absorb high radial loads as well as axial loads. The permissible level of the axial load depends on the outer ring’s profile and the rolling element used. Yoke type rollers are available with or without axial guidance, open or sealed.

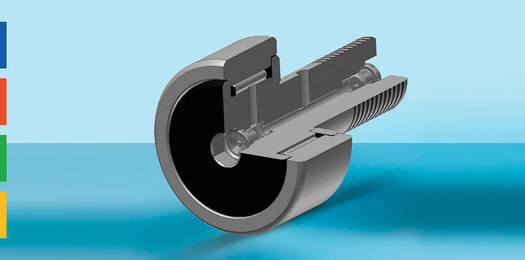

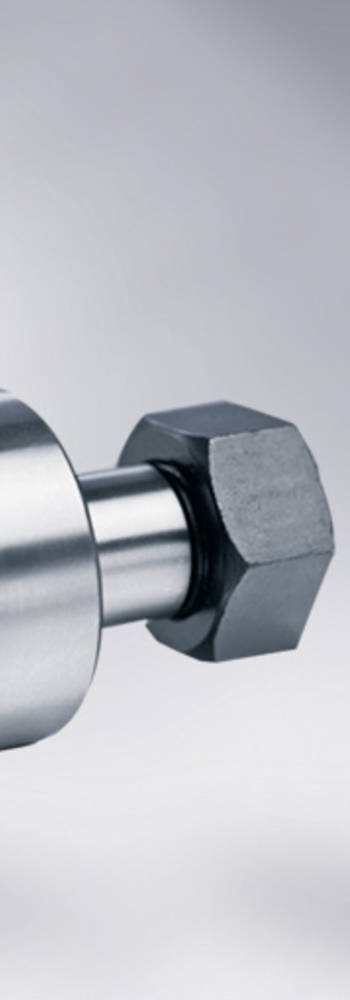

Cam followers are yoke type rollers sealed on both sides and with axial guidance and pins to simplify attachment to the mating structure. In general, the pin with the hardened raceway replaces the inner ring. Cam followers can be re-lubricated thanks to lubrication holes in the pin and corresponding lubrication nipples. The outer ring sheath has a spherical or cylindrical profile.

Track rollers are sealed single-row or double-row ball bearings with a thick spherical or cylindrical outer ring. The design corresponds either to a deep groove ball bearing or to an angular contact ball bearing. They are sealed on both sides and have either an inner ring or a pin.

Yoke type rollers, cam followers and track rollers are each available in numerous designs that differ from each other in terms of the rolling elements used and the design of the inner ring. The increasingly demanding requirements of automation result in the constant further development of this type of rolling bearing with respect to efficiency and performance capabilities.