Ready-to-mount cam followers

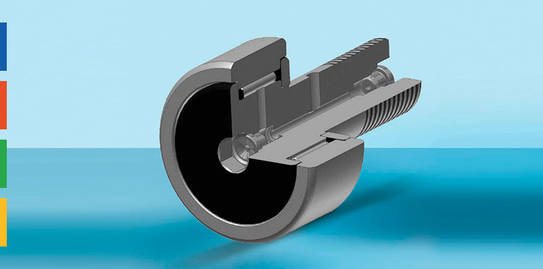

The new KRV-..-2SK/KR-..-2SK bearing series is available with a stud diameter of 10 to 30 mm in a steel and stainless steel design as well as cage-guided for high speeds or as a full complement variant for high loads. A hexagon socket on both sides of the cam follower guarantees a better frictional connection when fixing the cam followers during installation. Installation is also facilitated by the precisely maintained tolerances of max. 0.006 mm with a pin diameter of 2.5 mm (0.021 mm at ø 30 mm). The concave lubrication nipple integrated on both sides enable the lubrication of the cam followers both via the needle side and via the stud side.

It is no longer necessary to drive in a separate lubrication nipple. The new cam followers thus require less installation space and maintenance work. Moreover, a central lubrication system can be installed. Depending on the operating conditions, the lubrication intervals vary between six months and two years for cam followers with cage-guided rolling elements and one to six months for the full complement variant.

For the outer ring profile, users can choose between an optimized convex or cylindrical profile (X design). The cam followers from the NUKR series, with stud diameters of 16 to 30 mm, are characterized by a double-row, full complement set of rolling elements. This allows them to handle moderate axial loads in addition to high radial loads. All bearings are available in versions with or without an eccentric, pre-lubricated ex works and therefore ready-to-mount.

The ready-to-mount, compact cam followers are very similar in design to yoke type track rollers. They can therefore support very high radial loads, and the special profiling of the outer ring allows them to compensate for impact loads and minor axial loads resulting from misalignment. The profiling also ensures lower edge stresses in the event of angle misalignment and lower wear on the guide raceway. Moreover, the excellent processing and dimensional tolerance allows highly precise curved and linear movements to be achieved.

The types of bearings that are to be processed depends on the area of application. Findling Wälzlager GmbH offers a wide variety of roller member combinations, such as a ball bearing and needle roller bearing pairing for lower axial loads or a solution based entirely on cylindrical roller bearings for very high axial loads. The radial and axial bearing areas work independently of one another. This ensures that these areas do not interfere with each other’s running accuracy. Unlike in conventional bearings, no equivalent load needs to be calculated for combined bearings because each individual bearing part only absorbs either radial or axial forces.

- New products

- Cam followers

- Industries