Roller bearings and plain bearings for the fan and ventilation industry

The use of roller bearings on the fan market ranges from small consumer products to large, industrial ventilation of mines, tunnels or processing plants. The ever growing requirements for process reliability using heat recovery technology is also causing the demand for dependability to rise. Vibrations due to imbalances pose a significant challenge. Other challenges include classic installation problems with housing bearings due to adapter sleeves that affect the bearing clearance and radial runout accuracy of the bearing. Bearings that are also directly exposed to the flow of air require excellent sealing technology to protect against penetrating dirt and leaking lubricant. In tunnel construction and mining in particular, high-temperature resistance is necessary in order to guarantee emergency running properties in the event of a fire.

Allow us to surprise you with the sophisticated technical possibilities we can offer you to solve your challenges. Get in touch with us.

ABEG® in aviation technology

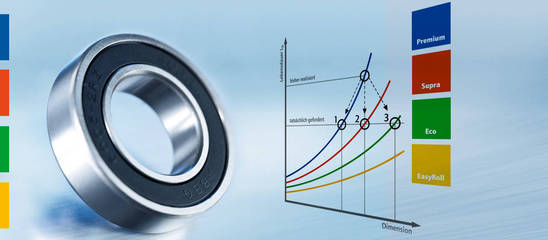

The choice of sealing technology and lubricant plays a particularly significant role in achieving the desired service life for small and flat fans. ABEG® gives you the option of freely combining equipment components like non-contact seals, lubricants, and bearing clearance classes in our Premium and Supra performance classes. During the initial design process, the axial forces that occur are a critical variable and often cause noise problems that have to be prevented with an optimized raceway geometry and quality.

In the case of industrial fans, the process heat to be conveyed and the emergency running properties in the event of a fire must be taken into consideration. Our range of tailor-made, function-oriented bearing technology makes it possible to quickly select the right bearing technology for your application.

Product recommendations for ventilation technology

Hybrid housing bearings for extreme temperatures

Technical ceramics are among the latest materials for roller bearings. As a material, they have above-average durability, and they’re thermally stable, electrically insulating and comparatively environmentally friendly and cost-effective. Stainless steel is also very dimensionally stable at high temperatures. That is why the temperature-resistant housing bearings consist of a stainless steel housing and bearing inserts of different designs that can be combined with one another in almost any way.

| Series | Description | Area of application |

|---|---|---|

| UC-2..-Y1 | bearing insert with ceramic balls | up to 180°C |

| UC-2..-Y2 | like Y1, but bearing insert made of stainless steel | up to 230°C |

| UC-2..-Y3 | like Y2, but cage made of solid lubricant | up to 400°C |

| UC-2..Y7 | bearing insert made of special stainless steel, cage made of fluorine resin | clean room conditions |

For detailed information, see the FYG catalog of the CeraBall series.

Miniature deep-groove ball bearings

Low noise levels play an especially big role in the medical field when it comes to reducing patient stress and allowing medical staff to stay concentrated. Finding the right lubricant for lifetime lubrication is not a trivial task if you look at the variety of adjusting screws. Errors can lead to premature failure here too. For example, only a lubricant change in an eccentric bearing of an inhalation device’s atomizer was able to ensure the desired service life. More information can be found on our lubricants product page.

ABEG® eXtreme series

Findling Wälzlager’s special product range is divided into four series: Xforce, Xspeed, Xtemp, and Xclean. This allows different requirements to be met with respect to operating conditions. Xforce bearings are solutions for high loads at low rotation speeds in which there are unfavorable tribological conditions and lubrication film build-up cannot reliably occur with standard solutions. During the development of the Xspeed series, on the other hand, high speeds and energy efficiency were the focus. The Xtemp series ensures temperature stability in excessively hot or cold conditions. The Xclean series provides robust bearing technology for corrosive ambient conditions as well as special designs for clean room applications.