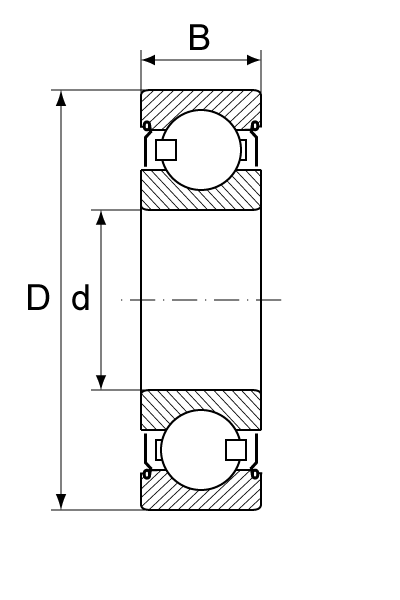

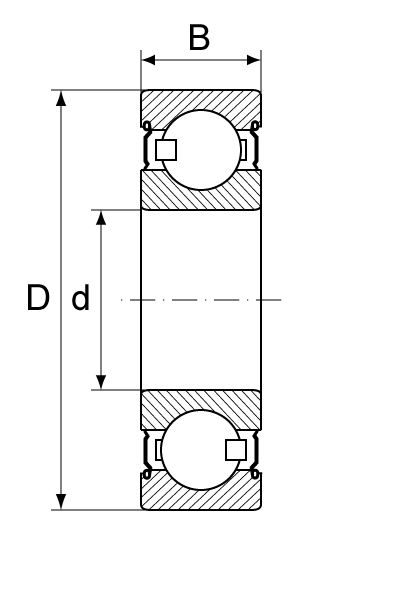

Deep-groove ball bearings

according to DIN EN ISO 625-1

Deep-groove ball bearings are versatile, self-retaining bearings with one-piece outer rings, inner rings and ball-cage assemblies. These simply designed products, which are durable and easy to maintain during operation, are available in single-row and double-row as well as open and sealed variants. Because of their very low frictional torque, deep-groove ball bearings are suitable for high and extremely high speeds.

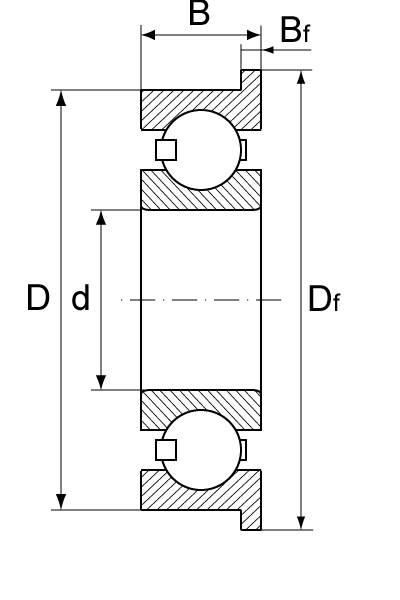

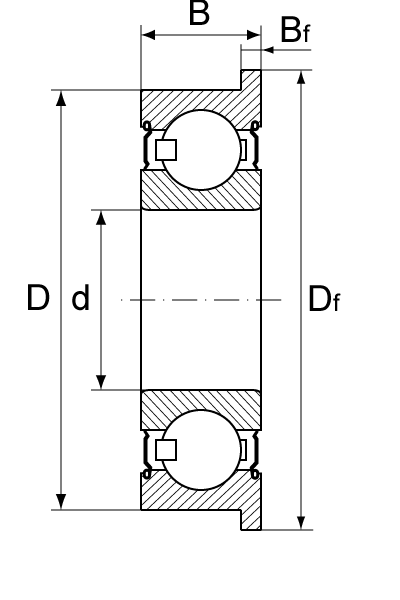

Deep-groove ball bearings with a flange have a rib on the outer ring, which allows them to be secured axially against shifting.

Product range

| Series | Description | available in ABEG® performance classes | |||

|---|---|---|---|---|---|

| 6xx MR-xx | Miniature deep-groove ball bearings < 10mm shaft diameter |  |  |  |  |

| 60 - 62 - 63 - 64 | Standard bearing ≥ 10mm shaft diameter |  |  |  |  |

| 67 - 68 - 69 | Thin-section bearing for particularly compact installation situations |  |  |  |  |

| 160 | Dimension series 160 as an intermediate solution for thin-section bearings, also available in 2RS |  |  |  |  |

Deep-groove ball bearings made of stainless steel

Depending on the material used, stainless steel deep-groove ball bearings have different anti-corrosive properties. Since stainless steel is difficult to temper, its load rating is reduced when compared to chrome steel. As standard practice, we supply rolling bearings made of the materials AISI420, AISI440C and AISI316L. Deep-groove ball bearings made of stainless steel have the suffix "-SS" for "stainless steel". For more details, see the technical properties of the materials.

Deep-groove ball bearings with a flange

| Series | Description | available in ABEG® performance classes | |||

|---|---|---|---|---|---|

| F-6 MF | Miniature deep-groove ball bearings < 10mm shaft diameter with a flange |  |  |  |  |

| F-60 F-62 | Standard bearing ≥ 10mm shaft diameter with flange |  |  |  |  |

| F-68 F-69 | Thin-section bearings with a flange for particularly compact installation situations |  |  |  |  |

- Bearing clearance classes C2, CN, C3 and C4

- | Fa - axial load

- | Noise test by decibels

- | Noise test by vibration level for deep groove ball bearings

- | Noise test by vibration level for tapered roller bearings

- | P - dynamic equivalent load

- | PN/P0 tolerance class for radial bearings (without tapered roller bearings)

Technical information

Inadequate sealing can allow external environmental conditions to negatively impact the ball bearings running characteristics and thus its service life. For this reasons, rolling bearings must be protected by seals in the best possible way.

Ball bearings with seals on both sides are generally lubricated for life.

At the same time, seals also prevent lubricants from leaking.

ZZ / Z

Sheet metal lid with a split seal effect. Only protects against coarse contamination. Only prevents grease from escaping to a limited extent; particular care is required when the grease becomes viscous, i.e. more liquid, because the risk of grease leaks increases. In such cases, a different viscosity class should be chosen for the grease, or a contact/non-contact seal should be used instead.

2RS / RS

Contact seal with effective sealing that protects against coarse and fine contamination. Also has very effective sealing that protects against lubricant leaks and therefore a long service life. By default, the seal consists of nitrile rubber and has a temperature resistance of -40 °C to +100 °C.

Note: These seals have different designs depending on the manufacturer. See also 2RT, LLU, VV, DD as special designs of a 2RS seal.

DD / D - LLB / LB - VV/V

Attached seal, double-lipped design. One lip rests axially against the inner edge of the groove, and the second can be a contact or non-contact seal for protection against penetrating foreign bodies that is oriented outward. The excellent seal also ensures reliable protection against aggressive paper dust and fine dirt particles.

LLB / LB - 2RZ / RZ - UU / U

Non-contact seal, usually inserted into a groove. Speed limits correspond to those of ZZ bearings. Very good seal, low internal heating due to friction of the seal, which also makes it very energy efficient. Popularly used in rotary encoders. Effective sealing, even against grease leaks.

2RT / 2RS1

Contact seal with excellent sealing effect against penetration of liquids into the bearing. Water tight to a limited extent because the sealing lip is pressed on more strongly due to a higher external pressure. Coarse and fine contamination is kept out very effectively. Effective sealing against grease leaks. The seal consists of nitrile rubber (NBR) as standard and has a temperature resistance of -40 °C to +100 °C.

The bearing clearance of a bearing is identified by means of its C mark (C0, C2, C3 ...).

C0/CN: standard bearing clearance class. This mark is usually omitted.

C2: decreases bearing clearance

C3: higher bearing clearance than C0/CN

C4: higher bearing clearance than C3

C5: higher bearing clearance than C4, used in particular in high-temperature bearings.

Special tolerances based on customer specifications: CX.Y (upper dimension X in µm, lower dimension Y in µm).

Abutment dimensions and radial runout accuracy have a decisive impact on the service life and function of rolling bearings. The selection of the shaft, housing and bearing tolerance should therefore always be checked in advance.

The following tolerance classes are available:

- Standard tolerances available ex stock: P0/PN

- Special tolerances: P6, P5

Cage types may vary depending on the size and application type. We carry various cage designs made of steel sheet and plastics.

| Cage designs | Mark | Comment |

| Sheet steel | J | Can be designed as a ribbon cage or riveted cage |

| Brass sheet | Y | |

| Glass fiber reinforced plastic | TV, TN, KU | Glass fiber content 25%, (standard), alternatively 30%, 40% |

A lubricant selection that is precisely tailored to the application conditions contributes disproportionately to the service life both in a positive and in a negative sense. For this reason, the technical and economical optimization of lubricant is an important contribution made by our application consulting.

An essential property of greases and oils is the reliable mechanical separation of the rolling element from the raceway. Depending on the application, you need special types of grease to achieve this function. The following properties in particular affect the function:

- the starting and operating temperature

- the speed of the bearing

- the external ambient conditions (moisture, contamination, vapors/gases...)

Our application engineers would be happy to analyze your application conditions and recommend suitable lubricants.

More information on special lubricants Contact for applications consulting

We use the following lubricant manufacturers as standard:

- Kyodo Yushi

- Klüber Lubrication

- Shell

- Lubcon

- Mobil

- Fuchs

We would be happy to make you a concrete offer for special processing, including the use of greases, oils or preserving agents specifically requested by you.

Rings

Outer and inner rings are manufactured from 100Cr6 (German standard), SUJ2 (Japanese standard) or GCr15 (Chinese standard) as standard.

Stainless steel products according to the AISI standard: AISI420, AISI440, AISI630 ...

Cage

Steel sheet cages are manufactured from DC01A/ST12 as standard.

Plastic cages (suffix TN, TV,TVP ...) may have different specifications but are usually made of polyamide. High-temperature designs made of PEEK.

Seals

Seals are manufactured from NBR (acrylonitrile butadiene rubber) as standard. This results in an operating temperature of -30 °C to +100 °C, even if the grease permits a higher temperature. The low chemical resistance makes other sealing materials necessary, which we would be happy to select for you as part of the application consulting:

- HNBR

- ACM

- FKM/FPM (also known under the brand name Viton).

©Viton is a protected trade name of DuPont Dow Elastomers L.L.C.

Findling Wälzlager has already realized more than 1,500 drawing parts for its customers. We will find you an economically and technically optimal solution for your application from the combination of ABEG® performance class and designs. You can trust 100 years of experience in rolling bearing technology.