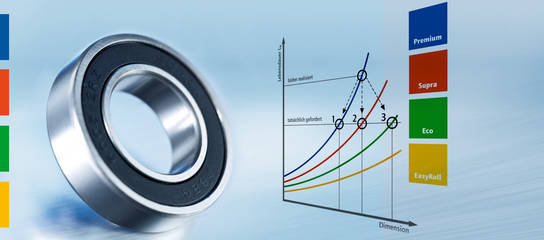

New perspectives for mechanical engineering through flexible special greasing

Who greases rolling bearings? We grease rolling bearings.

We offer roller bearing lubrication as a service for companies that don’t have their own lubrication system or suitable part cleaning machines for special grease or who simply lack the know-how and resources to do so. We are largely free when it comes to selecting greases. For example, we use greases manufactured by Shell, Rhenus, Lubcon, Kyodo Yushi, Esso, Mobil and many others, including special greases provided by customers. Our PPAP-documented and audited processes meet the highest requirements for part cleanliness and prevent contamination by foreign substances. Filling quantities and requirements for filling weights are guaranteed by suitable process monitoring procedures. We have already successfully processed small quantities of grease. There are hardly any upper limits to this because we can also reliably fill large spherical roller bearings thanks to various greasing systems.

With two dosing systems for roller bearing lubrication and a special cleaning system for removing preservatives (oil, wax), we are able to manufacture special bearings on small and medium scales of up to 1,000 units per batch size. Custom roller bearing lubrication is of interest for customers who cannot or do not want to take on such complex tasks in their own production process. In addition, the lead time for sampling with special roller bearing greases can be drastically reduced by re-greasing standard products from stock. We can also quickly carry out sampling with different ball bearing greases to test the best possible application suitability.

The custom and flexible roller bearing greasing means that we have created an offer that opens up new vistas for mechanical engineering in times of rising customer requirements with regard to flexibility and speed.

Economical dosing systems for roller bearing greases

We have reliable and economical greasing systems for dosing expensive PTFE roller bearing greases. These systems rule out carry-over of other ball bearing greases and oils and minimize line residues. Since we have to lubricate numerou bearing types, including ball bearings, tapered roller bearings, spherical roller bearings and needle-roller bearings, we rely on two different systems. They also allow minimal roller bearing grease quantities from 0.05 g to be processed, and grease filling quantities of up to 80% of the free space can be achieved. By the way: Since preservation with oil is not possible when using PTFE and other special greases, other packaging methods have to be taken into consideration. If necessary, such roller bearings are therefore packed into so-called VCI rolls or bags, which produce an atmosphere of protective gas, after greasing. This allows roller bearings to be manufactured with a technically dry surface, which may be required, for example, in optical measurement technology.

The advantages of custom roller bearing lubrication at a glance:

- We do all of the complex roller bearing greasing for you

- Complete process documentation (PPAP) from the receipt of goods to packaging

- Greasing of provided roller bearings, including batch tracking

- Speed and flexibility in special production thanks to flexible greasing of ball bearings and roller bearings

- Small to medium batch sizes

- Technically dry surfaces can be achieved

- Short lead time for sampling, including for different greases

![[Translate to Englisch:] Wälzlagerbefettung [Translate to Englisch:] Wälzlagerbefettung](/fileadmin/_processed_/5/5/csm_sonderbefettung-waelzlager-findling_94bc0b0cea.jpg)

![[Translate to Englisch:] Dosieranlagen für Wälzlagerfette [Translate to Englisch:] Dosieranlagen für Wälzlagerfette](/fileadmin/_processed_/c/f/csm_dosieranlagen-fuer-waelzlagerfette-findling_4718cf7310.jpg)