Plain bearings and roller bearings for the robotics and automation market

A high degree of quality and durability is a basic requirement for electronic, pneumatic, hydraulic and mechanical components in robotics and automation. Findling Wälzlager offers premium bearing technology for this market. We have standard products and special solutions for individual requirements in our product range. The high-quality materials and outstanding performance characteristics of our products are bound to impress you.

Application-specific roller bearings

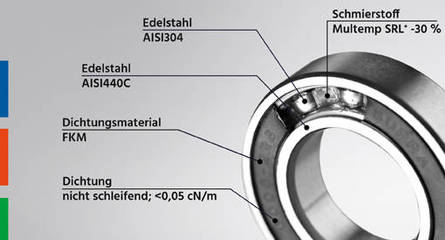

Findling’s experts work passionately every day to find the technically and economically optimum bearing for every application. The same also applies to special applications in which experts define all the necessary specifications together with the customer and then develop the ideal roller bearing. Materials, lubricants, and seals play a major role here, but so does the cage design under some circumstances, as is the case for deep-groove ball bearings used in the robots of a renowned manufacturer.

ABEG® for robotics

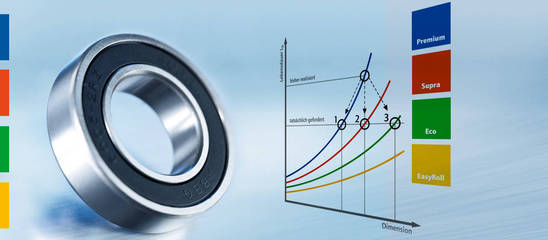

A new trend is emerging: from highly dynamic production robots to collaborative robots that can be used flexibly. The latter has to be designed in accordance with different standards, even with respect to roller bearing technology.

Robotics | autonomous | collaborative |

|---|---|---|

| Area of application | production | assembly |

| Optimization criteria |

|

|

| ABEG® performance class |

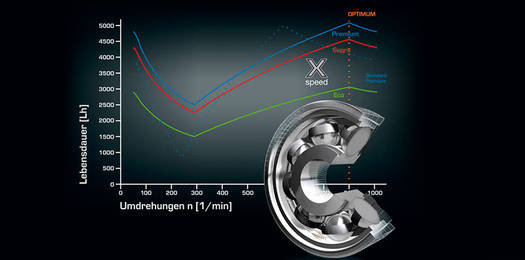

Our ABEG® performance classes allow you to always have access to a technical and economical solution for both growing and reduced demands. We will find you the optimum product and guarantee competitiveness throughout its entire life cycle. Our ABEG® eXtreme series enables you to push the boundaries of what is technically feasible even further.

Product recommendations for robotics, automation and sensors

Thin-section bearing: quality with a small cross section

Thin-section bearings can easily solve problems in applications with little installation space and are readily used in applications where large shaft diameters are desired in cases of very small bearing cross sections. This was the case for the swivel unit of a cornering light with the 6701-ZZ bearing type. This thin-section ball bearing has a shaft diameter of 12 mm, an outer diameter of 18 mm, and a width of just 4 mm.

Installation space comparison with a constant shaft diameter of 12 mm:

| Bearing type | 6701-ZZ | 6801-ZZ | 6901-ZZ | 6000-ZZ | 6201-ZZ | 6301-ZZ |

|---|---|---|---|---|---|---|

| Outer diameter | 18 | 21 | 24 | 28 | 32 | 37 |

| Width | 4 | 5 | 6 | 8 | 10 | 12 |

Challenges in sealing technology

The delicate structure of the rings and the out-of-roundness also cause problems with regard to sealing technology. In an uninstalled state, there is often a gap, and the seal does not fully contact the inner ring. For this reason, a lot of manufacturers no longer offer any contact 2RS seals at all, but only “non-contact” seals. Our ABEG products, however, continue to be available in all desired designs: 2RS: contact, 2RS-LLB: non-contact, and in ZZ with metallic dust shields.

Product range

Findling Wälzlager’s product range includes thin-section bearings with inner diameters ranging from 3 mm to 220 mm. Maximum precision is even guaranteed for the 67 series with an extremely thin cross section. The thin-section bearings are available in both chrome and stainless steel designs. Food-safe greasing is also possible upon request.

Needle roller thrust bearing and axial cylindrical roller bearings

Axial needle-roller bearings

With minimal installation height in thrust bearings and with very high load ratings, already available starting from a shaft diameter of 4 mm and going up to 160 mm.

Unlike axial ball bearings, the AXK series can support higher loads and transfer higher forces thanks the larger contact surface of the needles. Thrust bearing washers without ribs are usually used as parallel partners. Their axial installation height is equal to the diameter of the needles plus the thickness of the washers. The thrust washers (AS series) have an installation height of only 1 mm. However, the adjacent component must be sufficiently rigid and dimensionally accurate. The more solid track washers (LS series) can, like the AS washers, be used as housing and shaft washers and therefore do not permit more accurate centering. Housing washers are externally centered, shaft washers are internally centered, and they are used in combination with axial cylindrical roller bearings.

Combined needle-roller bearings consist of a heavy-section radial needle-roller bearing and a thrust bearing part that can consist of an axial ball bearing or an axial cylindrical roller bearing. If both radial and axial forces need to be transferred in a small installation space, these series are recommended.

ABEG® eXtreme series

Findling Wälzlager’s special product range is divided into four series: Xforce, Xspeed, Xtemp, and Xclean. This allows different requirements to be met with respect to operating conditions. Xforce bearings are solutions for high loads at low rotation speeds in which there are unfavorable tribological conditions and lubrication film build-up cannot reliably occur with standard solutions. During the development of the Xspeed series, on the other hand, high speeds and energy efficiency were the focus. The Xtemp series ensures temperature stability in excessively hot or cold conditions. The Xclean series provides robust bearing technology for corrosive ambient conditions as well as special designs for clean room applications.