Linear technology

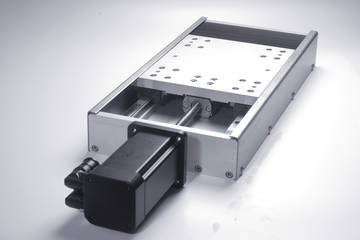

When it comes to linear motion, the principle of the roller bearing (rotating movement) is used to cover a defined distance in an energy-efficient and quiet manner. Balls, needles, and cylindrical rollers are also used as rolling elements here. Linear systems are easy to maintain and lubricate and do not require a running-in phase. High precision makes highly dynamic movement possible. Progress and technical innovations show that further considerable improvements should be expected in this technology. It is for this reason that our product range is constantly growing. Modern linear systems can be equipped with position measurement and braking systems. However, it’s still impossible to imagine our product range without the classic linear bushing. After all, it’s the only way to create a “self-supporting” design.

Linear guidance systems are more sensitive to impacts and a bit louder than plain bearings. To make up for this, they are characterized by high true running and positioning accuracy along with high stiffness and a long service life. In addition to this, international standards ensure interchangeability. This results in a high degree of flexibility when it comes to the maintenance of linear technology.