Our expertise for your industry

Roller bearings are installed in all kinds of packaging machines, canning plants, thermoforming machines, etc. and need to meet special requirements. Even though the bearings are exposed to extreme conditions, a long service life must be guaranteed because downtime can be costly. Customers from the packaging industry therefore require

- reliable and maintenance-free bearings

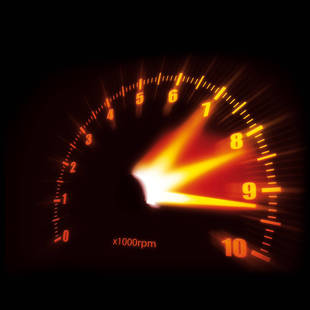

- for high cycle rates

- that are resistant to cleaning agents, and

- meet hygiene requirements

ABEG® in packaging technology

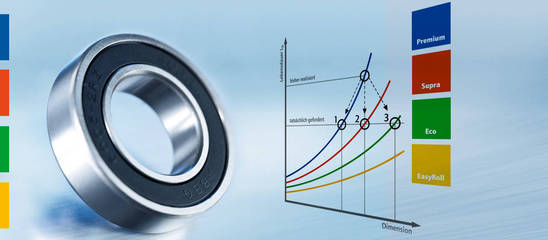

The load ratings of roller bearings often play a minor role in the packaging industry. The background: The service life of these roller bearings exceeds requirements. In terms of design, this results in classic oversizing, which is uneconomical for the customer. In these cases, there is no need for premium products. Using the ABEG® method, Findling can easily, quickly and reliably help achieve savings – for example by switching to lower-cost roller bearings in a different performance class that nevertheless meet the requirements for the respective application all along the line.

Our customers include manufacturers of bag making machines, canning plants, blister packaging for medical products, and thermoforming machines for packaging sausage and cheese. Thanks to our high level of application expertise and flexibility, Findling Wälzlager is the ideal partner for these manufacturers of special machinery and can offer fast delivery with our large inventories.

Packaging food comes with special requirements, such as optimum corrosion protection, the best possible hygiene standards, and resistance to aggressive chemicals. Low-corrosion stainless steel roller bearings are ideally suited for this. In Findling Wälzlager’s extensive stainless steel portfolio, you will find, among other things, york type track and cam followers, needle-roller bearings, housing bearings, self-aligning ball bearings, thrust bearings and deep-groove ball bearings.

Flange bearings or die-cast aluminum bearings are used for sealing mechanisms and drive rollers for conveyor lines and tracks. They are very small, lightweight and corrosion-resistant. The Clean and Silber series are also suitable for higher loads. Findling also has galvanized steel sheet housings and stainless steel designs in its product range in which a bearing insert is clamped. Three models are available: plummer block (PP), 2-Loch flange bearings (PFD) und 3-Loch flange bearings (PFL).

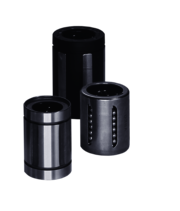

Sliders that move up and down are not least a common application in packaging machines. Linear bushings, which make linear motion possible, are readily used for this. Findling has various products in its range: in addition to normal linear bushings (NKB), there are also compact linear bushings (KKB) and not least super ball bushings (SKB), both in standard and stainless steel designs.

Product recommendations for the packaging industry

Die-cast aluminum and sheet metal flange bearings

Corrosion resistance, compact dimensions, and low weight: these are the advantages of die-cast aluminum bearings. The clean and silver series, which are suitable for high loads, are worth mentioning in particular here. The housings of these bearings are made of very light die-cast aluminum. Together with a stainless steel bearing insert, these solutions are corrosion resistant. By combining them with bearing inserts made of standard steel, it is possible to create very compact and easy-to-install bearing solutions with a shaft diameter of 8 mm. Findling also has galvanized steel sheet housings and stainless steel designs in its product range in which a bearing insert is clamped. Three models are available: plummer block (PP), 3-hole flange bearings (PFL), and 2-hole flange bearings (PFD). These solutions are very small, compact and light. The flange bearings are used, for example, in closing mechanisms in which long shafts are used to, for example, open and close bags. Flange bearings are also used in the drive rollers of conveyor lines and tracks.

Linear bushings

Linear bushings enable linear movements from A to B, allowing them to be used in packaging machines, for example for sliders that move up and down. Linear bushings are simpler in design than linear guidance systems and can be installed and adjusted intuitively. Findling has various products in its range: in addition to normal linear bushings (NKB), there are also compact linear bushings (KKB) and not least super ball bushings (SKB). Depending on the design, the sleeves/cages are made of solid steel or plastic with steel segments. Either chrome steel or stainless steel is used as a material. Linear bushings with plastic sleeves are suitable for ensuring low noise generation. Designs with raceway segments made of stainless steel and steel are designed for corrosive environments and have high load ratings.

| Link | Description |

|---|---|

| Samick manufacturer presentation (work in progress) | |

| Software ABEG® Quickfinder lineartools |

Stainless steel roller bearings

protected against corrosion

The use of stainless steel types such as AISI440C, AISI420, AISI316L or zinc/iron or zinc/nickel coatings allows us to achieve excellent corrosion protection.

Corrosion-resistant Xclean series roller bearings are ideally suited for the high demands of food packaging. They ensure the best possible hygiene standards, optimum corrosion protection, and resistance to aggressive chemicals. In Findling Wälzlager’s extensive stainless steel portfolio, you will find, among other things, yoke type track rollers und cam followers, needle-roller bearing, housing bearing, self-aligning ball bearing, axial deep-groove ball bearing and deep-groove ball bearing. Customers can choose the base material that is best suited for their application, for example stainless steel types AISI440C, AISI316L, AISI304, AISI420 or 100Cr6 roller bearing steel with zinc/iron or zinc/nickel coatings. Ceramics and high-performance materials such as AISI630 or titanium are also possible. Last but not least, seals are very important in this area of application because rough operating conditions necessitate proper protection of the inside of the bearing. If chemical resistance is required, seals made of HNBR, ACM and FKM can also be offered in addition to seals made of NBR. Special greases, in particular with H1-approved food-compatible grease, round out the product range.

ABEG® eXtreme series

Findling Wälzlager’s special product range is divided into four series: Xforce, Xspeed, Xtemp, and Xclean. This allows different requirements to be met with respect to operating conditions. Xforce bearings are solutions for high loads at low rotation speeds in which there are unfavorable tribological conditions and lubrication film build-up cannot reliably occur with standard solutions. During the development of the Xspeed series, on the other hand, high speeds and energy efficiency were the focus. The Xtemp series ensures temperature stability in excessively hot or cold conditions. The Xclean series provides robust bearing technology for corrosive ambient conditions as well as special designs for clean room applications.