Special roller bearings and industry-specific processes

Our processes and procedures will thrill you. We will even offer you a zero-defect strategy under very high cost pressure and subject ourselves to your audit. We are familiar with the automotive industry’s special requirements, for both products and processes.

- Quality assurance, confidentiality and logistics agreements

- Support for processes from the sampling phase all the way to series production

- Routine implementation of VDA requirements

- Continuous monitoring of production processes and quality indicators

- Handling of multi-year framework contracts

- Logistics solutions and framework agreements for long-term projects

- Coverage through high product liability insurance values for the automotive sector

We have a pre-audited large network of manufacturers for ball bearings, roller bearings and needle-roller bearings for the automotive industry. This makes it possible to quickly implement new projects for you. Our product range includes, for example, needle-roller bearings having a particularly high raceway accuracy and load rating, roller bearings with anti-corrosive coatings, ultra-light and compact ball bearings for weight and space savings, and energy-efficient bearing solutions.

ABEG® in the automotive industry

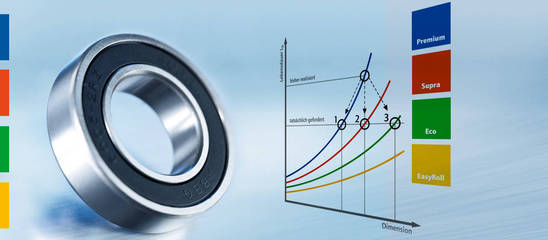

It goes without saying that only premium products are used in safety-critical applications. However, there is an ever-increasing range of auxiliary units and mechanical convenience features that make economical solutions necessary. With ABEG, we create new possibilities for technological progress in the luxury class, even in compact cars: from cornering lights, automatic tailgate opening and swing-out trailer couplings to central locking systems. We take the following into account here:

| Technical principles | Systemic principles |

|---|---|

|

|

Product recommendations for automotive industry

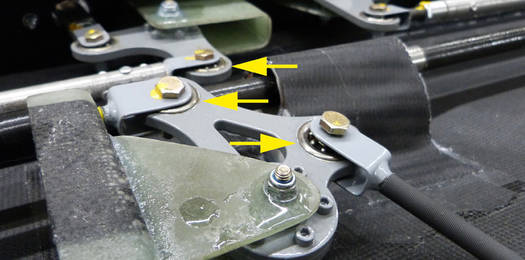

Thin-section bearing: quality with a small cross section

Thin-section bearings can easily solve problems in applications with little installation space and are readily used in applications where large shaft diameters are desired in cases of very small bearing cross sections. This was the case for the swivel unit of a cornering light with the 6701-ZZ bearing type. This thin-section ball bearing has a shaft diameter of 12 mm, an outer diameter of 18 mm, and a width of just 4 mm.

Installation space comparison with a constant shaft diameter of 12 mm:

| Bearing type | 6701-ZZ | 6801-ZZ | 6901-ZZ | 6000-ZZ | 6201-ZZ | 6301-ZZ |

|---|---|---|---|---|---|---|

| Outer diameter | 18 | 21 | 24 | 28 | 32 | 37 |

| Width | 4 | 5 | 6 | 8 | 10 | 12 |

Challenges in sealing technology

The delicate structure of the rings and the out-of-roundness also cause problems with regard to sealing technology. In an uninstalled state, there is often a gap, and the seal does not fully contact the inner ring. For this reason, a lot of manufacturers no longer offer any contact 2RS seals at all, but only “non-contact” seals. Our ABEG products, however, continue to be available in all desired designs: 2RS: contact, 2RS-LLB: non-contact, and in ZZ with metallic dust shields.

Product range

Findling Wälzlager’s product range includes thin-section bearings with inner diameters ranging from 3 mm to 220 mm. Maximum precision is even guaranteed for the 67 series with an extremely thin cross section. The thin-section bearings are available in both chrome and stainless steel designs. Food-safe greasing is also possible upon request.

Needle-roller bearings

Thin and lightweight, yet highly resilient

Needle-roller bearings perform their duty inconspicuously and are the design engineer’s last chance wherever maximum loads are required in small spaces. The line contact of needles in conjunction with high needle density in very small spaces results in the highest load ratings in roller bearing technology. Applications include use in crankshafts or in braking systems for commercial vehicles and railway technology. However, these products are also used in tailgate opening mechanisms and armrests.

Whether in the form of radial bearings or thrust bearings, of solid or lightweight series, this product range and its variety is comparable to that of deep-groove ball bearings. It is therefore advisable to have an expert at your side who has a good overview of the product range when you make your selection.

ABEG® eXtreme series

Findling Wälzlager’s special product range is divided into four series: Xforce, Xspeed, Xtemp, and Xclean. This allows different requirements to be met with respect to operating conditions. Xforce bearings are solutions for high loads at low rotation speeds in which there are unfavorable tribological conditions and lubrication film build-up cannot reliably occur with standard solutions. During the development of the Xspeed series, on the other hand, high speeds and energy efficiency were the focus. The Xtemp series ensures temperature stability in excessively hot or cold conditions. The Xclean series provides robust bearing technology for corrosive ambient conditions as well as special designs for clean room applications.

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/_processed_/b/f/csm_2022_Findling_preferred_certificate_3ba6bd9a0d.png)