Roller bearings for conveying technology...

... must meet very particular requirements: Depending on the area of application, it is necessary for them to cope with high loads, have good sealing efficiency or deliver a convincing performance with smooth running characteristics. In the case of custom-designed systems, customized bearing technology is also often needed. Customers from the food industry require a wide range of different stainless steel solutions, such as deep-groove ball bearings and self-aligning ball bearings or housing bearings. No problem: We score points with our full product range and diverse performance classes. In our comprehensive portfolio, customers will find technically and economically optimum roller bearings for every application. The product range includes high-end products from manufacturers such as NACHI or FYH and standard components from our ABEG® Eco performance class. Another bonus: the products are always available at short notice, meaning that customers don’t need to worry about delays in this regard.

ABEG® in conveying technology

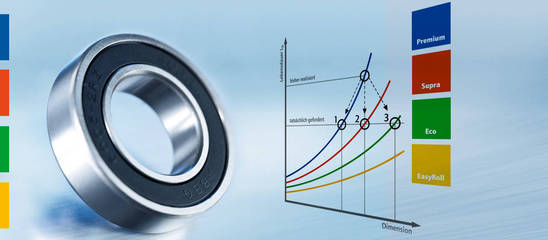

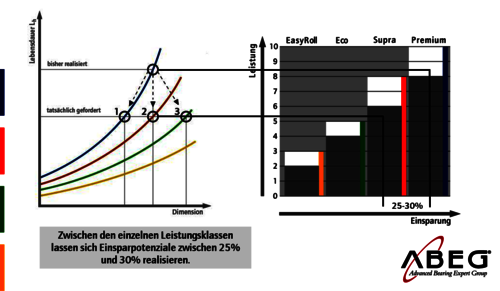

Hardly any other industry depends as much on functioning roller bearing technology under high cost pressure. Hundreds of millions of roller bearings are installed each year, and conveying technology also makes up over 50% of Findling Wälzlager’s sales volume. The demands on performance are particularly varied due to bearing points that are subjected to a wide range of loads, and the need for particularly energy-efficient bearing technology keeps growing. Good sealing technology and friction minimization must always be in harmony here because the ambient conditions can be extremely rough. With ABEG®, we offer our customers the possibility to quickly determine the optimum performance class for their application. Our ability to combine them with different functionalities makes us a universal provider for all conveying technology manufacturers.

Product recommendations for conveying technology

Economical solutions from our Eco performance class

For the sake of honesty and transparency, it should be pointed out that the majority of roller bearings used in conveying technology are oversized. If you were then to rely on high-priced premium products, the solutions would usually be unaffordable. This makes technically reliable, standard-compliant solutions all the more important, which is why we’ve bundled them in our Eco product range.

A standardized product design, efficient production process, and high production batch sizes make it possible to have a particularly attractive price/performance ratio in this performance class.

Nevertheless, we offer a wide range of different configuration options.

- Sealing technology (contact, non-contact) for friction minimization or improving seals

- Sealing materials (NBR, ACM, FKM) for thermal and chemical resistance

- Greasing

- Cage designs

- Bearing clearance (CM for electric motors, C0, C3, C4)

- Tolerance classes (P0, P6)

EasyRoll for particularly price-sensitive applications

For applications where the price is particularly important, we also offer ball bearings in the EasyRoll performance class.

- optionally available in cartridge packaging (reduced packaging volume)

- ideal for very high quantities

- lower disposal costs for packaging

We’ve trimmed this performance class for efficiency for particularly cost-sensitive applications.

- Reduction of any unnecessary packaging, meaning delivery usually in “cartridge packaging” or bulk packaging

- High quantities per pallet (low cargo compartment costs)

- Extremely large production batches

- Standardized greasing and sealing technology

- C0/CN or C3 bearing clearance

- P0/PN tolerance class

- Steel sheet cage (glass fiber reinforced plastic cage upon request)

Housing bearings with outstanding sealing technology

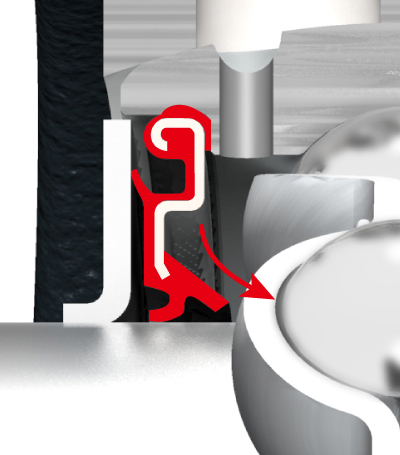

FloBack and flinger ring

UC series bearing inserts come with effective sealing as standard. The flinger ring rotates with the inner ring and immediately slings away coarse dirt upon impact. The FloBack seal located behind the flinger ring protects the bearing interior against fine dirt.

Our premium manufacturer FYH meets the increasing demands for functioning protection against contamination with various seal designs that are incorporated into the bearing and can be supplemented by additional accessories. Steel sheet caps are clipped into a groove in the housing (E design = with groove). The interior can be filled with grease to improve the sealing effect even further and to bind dirt. Cast caps can be screwed onto the corresponding housing to protect against very coarse dirt (F design). FYH offers backside guards to ensure that flange bearings are better protected from the rear.

The images are taken from FYH’s main catalog.

ABEG® eXtreme series

Findling Wälzlager’s special product range is divided into four series: Xforce, Xspeed, Xtemp, and Xclean. This allows different requirements to be met with respect to operating conditions. Xforce bearings are solutions for high loads at low rotation speeds in which there are unfavorable tribological conditions and lubrication film build-up cannot reliably occur with standard solutions. During the development of the Xspeed series, on the other hand, high speeds and energy efficiency were the focus. The Xtemp series ensures temperature stability in excessively hot or cold conditions. The Xclean series provides robust bearing technology for corrosive ambient conditions as well as special designs for clean room applications.