Robust bearing technology for construction machinery

The service life of roller bearings is especially dependent on working sealing technology in particularly rough environmental conditions. High loads also cause significant shaft tilting, which needs to be compensated. With our global network, we have access to highly specialized companies with innovative solutions for tasks like this. Our application engineers are going to surprise you with the amount of added value we can get out of your construction machinery, materials machinery and in mining applications:

- Longer service lives

- Less maintenance work

- More resilient housings with lower product weights

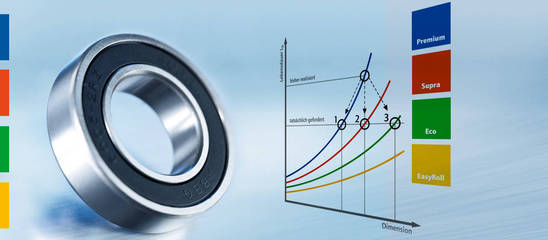

ABEG® performance classes for construction machinery bearings

High loads and low speeds place special demands on lubricants because load ratings alone cannot contribute to a long service life. Accordingly, it is important to focus on heavy-duty roller bearing greases and excellent sealing technology. Using the ABEG® method we identify functionally critical bearing points that can extend the overall service life of the unit through targeted optimization. At the same time, we avoid oversizing and help engineers achieve savings wherever it makes sense – for example by switching to lower-cost roller bearings in a different ABEG® performance class that nevertheless meet the requirements for the respective application all along the line. In doing so, we create economic room for industry-specific products, for example with excellent sealing technology.

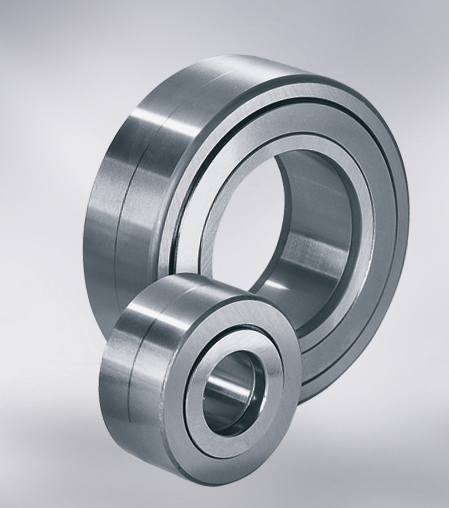

Ready-to-mount SRU spherical roller bearing units

- Sealed bearing units, equipped with a highly resilient spherical roller bearing

- Angular error compensation also in the seal

- High speed range, extremely high retaining forces on the shaft

- Innovative replacement for split pedestal bearings

- Housing made of high-strength EN-GJS-450 (GGG) cast iron

- Simple installation that is not prone to errors

Xforce housing bearings for extreme loads

- Durable housing bearings for heavy-duty applications and rough environmental conditions

- Ideal for use in construction machinery, plant engineering, conveyor lines, agriculture or in classic heavy engineering

- Extra solid design with a reinforced base for extreme loads

- 6 to 15 times increase in the service life thanks to the use of special greases

Application examples for construction machinery

Roller bearing innovations for mechanical engineering

In cases of demanding operating conditions, such as in construction machinery, roller bearings must be designed to be particularly robust in order to handle the high loads over the long term. Findling Wälzlager GmbH offers a comprehensive range of suitable solutions, from the robust housing bearings of the Xforce series and FYH’s innovative SRU units to standard roller bearings optimized for specific applications. The solution that ends up being used always depends on the respective application. Those who are unsure should seek out advice from an expert. Safety is ultimately the number one priority at construction sites, not least when it comes to the heavy-duty bearings installed in the machinery.

An individually adapted deep-groove ball bearing for vibrating plates

Findling Wälzlager has already completed many special projects for construction machinery. In 2016, a well-known German manufacturer was looking for suitable heavy-duty ball bearings for the latest generation of single-direction vibrating plates. This application case poses a design challenge. The technical requirements for the roller bearings were speeds of up to 6,000 rpm, centrifugal forces of up to 10 kN per bearing, operating temperatures of up to 100 °C, but above all extreme vibration loads. In this case, the decision was made to use a deep-groove ball bearing in the Supra performance class made of high-quality raw materials that was adapted to the cage design and bearing clearance. Our experts developed a ball-guided brass cage that is vibration resistant, has excellent dry-running characteristics, and operates with minimal friction. The latter also meant that the housing temperatures decreased and the oil lubrication could be designed for life, thus making the bearings maintenance-free.

Robust flange bearings withstand rough operation on construction sites

Findling roller bearings are also used in professional brick saws. PProducts that are designed for continuous use on construction sites must accordingly have a robust design. This also applies to all bearing components, such as type UCFL-206 housing bearings, which support the hinged motor plate and the cutting shaft in the block saw. The requirements are particularly demanding here. The cutting shaft is driven by the electric motor with a belt drive. The speed is 1,020 rpm here. A lot of dust is formed during the sawing process which gets into the interior of the bearing and can drastically reduce its service life. The D1 design ensures that the user can relubricate the bearing from the outside at regular intervals. During this process, foreign particles are driven out by the fresh grease and the service life is significantly increased.

Housing bearings with outstanding sealing technology

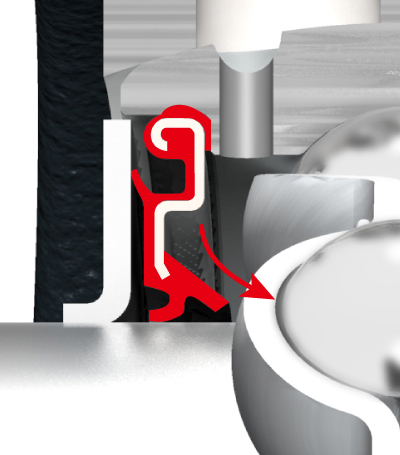

FloBack and flinger ring

UC series bearing inserts come with effective sealing as standard. The flinger ring rotates with the inner ring and immediately slings away coarse dirt upon impact. The FloBack seal located behind the flinger ring protects the bearing interior against fine dirt.

Our premium manufacturer FYH meets the increasing demands for functioning protection against contamination with various seal designs that are incorporated into the bearing and can be supplemented by additional accessories. Steel sheet caps are clipped into a groove in the housing (E design = with groove). The interior can be filled with grease to improve the sealing effect even further and to bind dirt. Cast caps can be screwed onto the corresponding housing to protect against very coarse dirt (F design). FYH offers backside guards to ensure that flange bearings are better protected from the rear.

The images are taken from FYH’s main catalog.