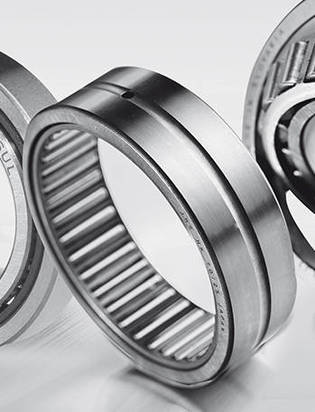

Needle-roller bearings

Needle-roller bearings are characterized by thin, cylindrical rolling elements. Despite their small cross section, they are highly resilient and are therefore used in applications where there is not much installation space.

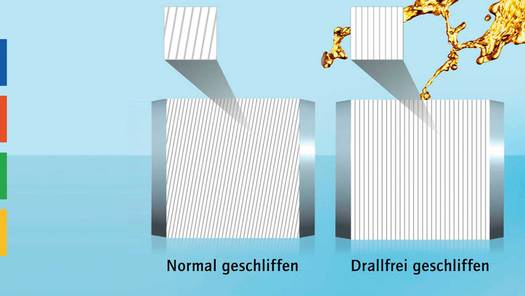

As is the case for ball bearings, needle-roller bearings generally come either in radial or axial designs. Radial needle-roller bearings with or without an inner ring only absorb radial forces and are designed for medium loads at medium speeds. They are primarily used in transmissions and in general mechanical engineering applications. Dispensing with an inner ring also makes it possible to reduce the size of needle-roller bearings. However, the shaft serves as a raceway in this case. To maintain full load-carrying capacity, it has to be hardened and ground.

Thanks to its many decades of experience with needle-roller bearings, Findling has built up special expertise from which customers can benefit. There are a few things to pay attention to when using needle-roller bearings. One example is greasing, which can be problematic in the case of needle-roller bearings due to small installation spaces: It is difficult to provide enough grease for an optimal lubrication situation. For lubrication, users should preferably use oil, in particular at high speeds. At medium speeds, external lubrication must be possible by means of a lubrication groove. Lifetime lubrication with grease is also possible at low speeds.

At Findling Wälzlager, needle-roller bearings are available in different sizes and designs. They are made of different types of steel, both with and without corrosion protection, with different cage designs and custom-made products.