Our expertise for heavy industry

The extreme operating conditions in heavy industry necessitate well-functioning sealing technology, protection against corrosion and compensation for shaft tilting, which occurs under high loads. Findling Wälzlager has further expanded its expertise and offers a product range with many innovative solutions that are optimized for these requirements. With Findling’s rolling bearings, users benefit from

- A longer service life

- Less maintenance work

- More resilient housings with lower product weights

Last but not least, customers benefit from the focused advisory expertise of learned best practices. If you are unsure, Findling’s application engineers would be happy to advise you. Safety is ultimately the number one priority in heavy industry, not least when it comes to the rolling bearings installed in the machinery.

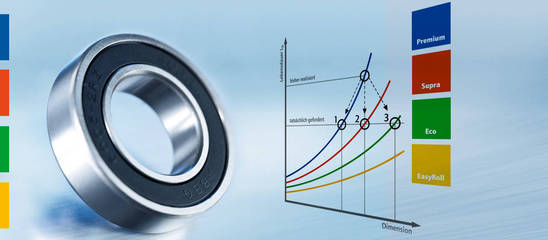

ABEG® in heavy industry

High loads and low speeds place special demands on lubricants because load ratings alone cannot contribute to a long service life. Accordingly, it is important to focus on heavy-duty roller bearing greases and excellent sealing technology. Using the ABEG® method, we identify functionally critical bearing points that can extend the overall service life of the unit through targeted optimization. At the same time, we avoid oversizing and help engineers achieve savings wherever it makes sense – for example by switching to lower-cost roller bearings in a different ABEG®-performance class that nevertheless meet the requirements for the respective application all along the line. In doing so, we create economic room for industry-specific products, for example with excellent sealing technology.

Product recommendations for heavy industry

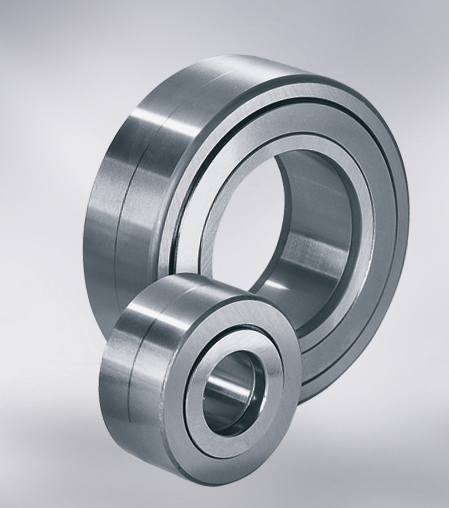

Housing bearings with outstanding sealing technology

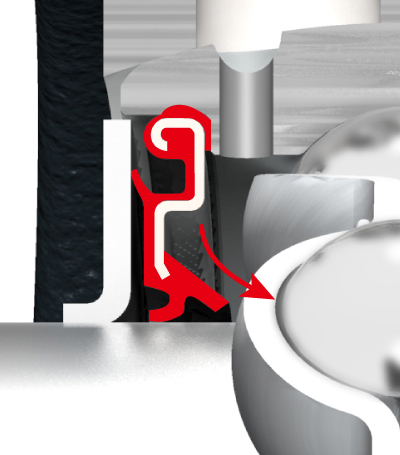

FloBack and flinger ring

UC series bearing inserts come with effective sealing as standard. The flinger ring rotates with the inner ring and immediately slings away coarse dirt upon impact. The FloBack seal located behind the flinger ring protects the bearing interior against fine dirt.

Our premium manufacturer FYH meets the increasing demands for functioning protection against contamination with various seal designs that are incorporated into the bearing and can be supplemented by additional accessories. Steel sheet caps are clipped into a groove in the housing (E design = with groove). The interior can be filled with grease to improve the sealing effect even further and to bind dirt. Cast caps can be screwed onto the corresponding housing to protect against very coarse dirt (F design). FYH offers backside guards to ensure that flange bearings are better protected from the rear.

The images are taken from FYH’s main catalog.