Mistakes when choosing rolling bearings: basing your choice on the "electric motor quality"

“The term electric motor quality is neither a seal of quality nor a guarantee of a desired running characteristic,” explains Klaus Findling, Findling Wälzlager GmbH’s Managing Director. “There aren’t any cross-manufacturer technical features that have to be implemented for such a claim.” All it means is that a minimum requirement for noise and vibration testing defined by the provider is met.

However, every roller bearing manufacturer defines its own plant standards, especially when it comes to vibration tests. This means that there’s no guarantee that direct comparisons can be made. In addition to this, the running characteristics are affected by the installation situation, as well as the interaction between various parameters in the roller bearing. The running characteristics essentially depend on the tolerance class of the connection dimensions (P0 is insufficient, it should be at least P6 on the inner ring), on the bearing clearance class (a restricted bearing clearance such as CM is recommended), and on the radial runout accuracy of the rolling element raceways. The lubrication is also particularly important. Making the wrong selection here can immediately wipe out any investments in a higher production standard. Multiple parameters and characteristics must therefore be in place for ball bearings to prove their worth in electric motors.

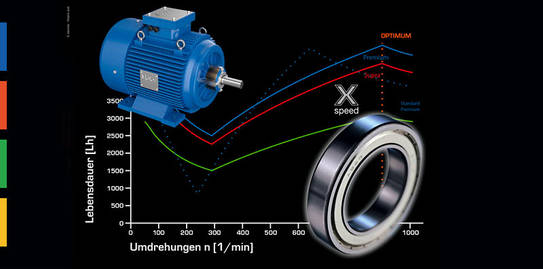

For electric motors, Findling Wälzlager offers a special series in which all the essential characteristics are combined. The Xspeed bearings are designed for high-speed applications. Their use is therefore also recommended in pumps, compressors, fans, rotary encoders or air-conditioning systems. Since running properties play a special role in this segment, Xspeed bearings meet the highest requirements when it comes to the surface quality and profiling of the raceways.

They are manufactured in tolerance class P6 with increased precision and radial runout accuracy. The bearing clearance is adapted to the high speeds by tightening the tolerance. This makes it possible to optionally adjust the residual bearing clearance based on the selection of the housing and shaft fit.

For a particularly long service life, lubrication and seals were optimized with respect to the requirements of high-speed applications. A special high-purity, viscous and low-noise grease with excellent start-up behavior ensures optimum operation at high speeds. The 2RSDD seal variant (axially abutting contact rubber seal inserted into the groove on both sides) reduces the internal heating of the bearing by a whole 10 °C. An even lower-friction (2RW) variant and a non-contact seal variant (LLB) are optionally available.

- Application engineering

- Konstruktiv newsletter

- Deep-groove ball bearings

- Industries

- Xspeed